Hazardous area lighting for explosive atmospheres (IECEx & ATEX certified luminaires)

Hazardous area lighting is specially designed for environments where there is a risk of explosion caused by flammable vapours, gases or dusts, guaranteeing optimum safety thanks to luminaires adapted to the level of danger. Sammode hazardous lighting also offers an unprecedented level of durability on the market.

As a specialist in hazardous area lighting, Sammode designs robust and durable solutions specifically for hazardous environments where there is a risk of explosion. Our hazardous lighting ranges are the result of our long experience and expertise in sectors such as chemicals, petrochemicals, onshore and offshore installations, and grain processing and storage. Thanks to our know-how, our ATEX lighting products guarantee reliable performance in hazardous areas, meeting the specific requirements of these industries.

Lighting adapted to ATEX environments

High material resistance for Sammode hazardous luminaires

304L or 316L stainless steel for external metal parts. Borosilicate glass, polycarbonate or coextruded polycarbonate/methacrylate.

Performance

Efficiency: our LED luminaires reduce energy consumption while guaranteeing optimum operation, even at extreme temperatures. Comfort: high performance and lighting comfort guaranteed.

Tightness - IP68/IP69K

IP68: totally waterproof for long-lasting performance. IP69K: weatherproof and resistant to high-pressure cleaning.

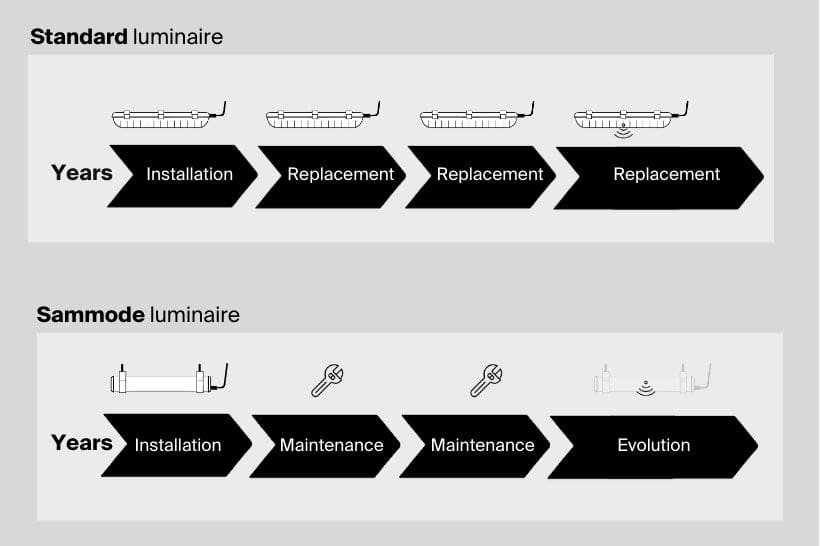

Durability, maintainability, upgradeability

Our robust, durable products are designed to be maintainable, with replaceable parts (spare parts available for a minimum of 30 years) and easy on-site maintenance. They evolve with your needs and new technologies.

ATEX environments:

safety and optimum performance in hazardous areas

| |||||||||||||||||||||||||||

Our commitments to support you

in your ATEX lighting projects

|

ATEX lighting projects: Sammode, your partner for support

We put experienced teams at your service, combining technical expertise and flexibility to meet the specific needs of your lighting project. Always ready to listen, our professionals are with you every step of the way, guaranteeing perfectly adapted solutions and ongoing support to ensure an optimal lighting installation. Thanks to a precise diagnosis of your needs and the location, we optimise every parameter to maximise the performance and efficiency of the lighting installation, giving you a perfectly tailored, long-lasting solution.

A long-term investment

with Sammode hazardous luminaires (ATEX/IECEx)

The life cycle of Sammode products is conceived in a global way, integrating each stage from design to end of life. Made from durable materials, the luminaires are robust and resistant, even in the most demanding ATEX environments. Installation is simplified, and servicing and maintenance ensure their performance over time. Our luminaires are evolutionary, offering the possibility of technological upgrades, and the majority of components are recyclable or reusable. This helps to reduce environmental impact while saving money.

Upgradeable lighting solutions :

economical and ecological

From conception to assembly, our products are designed with an evolutionary approach, allowing continuous adaptation to technological advances and the changing needs of our customers. This built-in flexibility ensures that each luminaire remains efficient and relevant over time, providing a scalable, durable and cost-effective ATEX lighting solution capable of meeting the most specific requirements.

Sammode expertise

Diagnosis and recommendations

We start by analysing your operating conditions, installation requirements and other specific needs, and then recommend the most suitable solutions.

Lighting studies

Our lighting studies are designed to identify the precise quantity of luminaires and quality of the lighting solution required, while minimsing the number of light sources and energy use.

Control systems

To reduce your energy bill and improve your lighting control, our experts will suggest the management solutions best suited to your situation.

Developing special products

As both designer and manufacturer, we systematically study the best technical solutions and are able to adapt them to meet your needs.

On-site testing and support

We can manage your project from start to finish, from studies to installation, including any tests required in actual operating conditions.

Ultimate 8-year warranty

We offer an ultimate 8-year warranty for most of our products, the only such offer available on the lighting market under intensive 24/7 operating conditions.

They trust us

We can offer the ideal product for each type of environment and specific requirements

|