Lighting in bus stations and depots

Public transport authorities use bus stations and depots as sites to park buses when not in use, refuel with gas or electricity, and carry out the necessary maintenance works and repairs. These sites are often partially indoors and partially outdoors, with highly specific lighting requirements.

The luminaires installed will vary depending on whether the area is used to maintain and recharge electric buses, or gas-operated buses, as lighting for the latter must be compatible with explosive risks (ATEX environment). Some indoor areas will be more subject to dirt, while some outdoor areas will face corrosion due to humidity and UV radiation. Lighting solutions require expert input from professionals such as Sammode, a source of custom support for long-lasting products and advice when designing lighting projects, aiming to optimise light points, particularly in view of the switch to LED.

Regular bus servicing operations and any repairs required are carried out in the maintenance workshops, contained areas where around-the-clock lighting is mandatory, including in broad daylight. Personnel working in these areas require quality homogeneous lighting to ensure the operations are completed effectively and for their own safety.

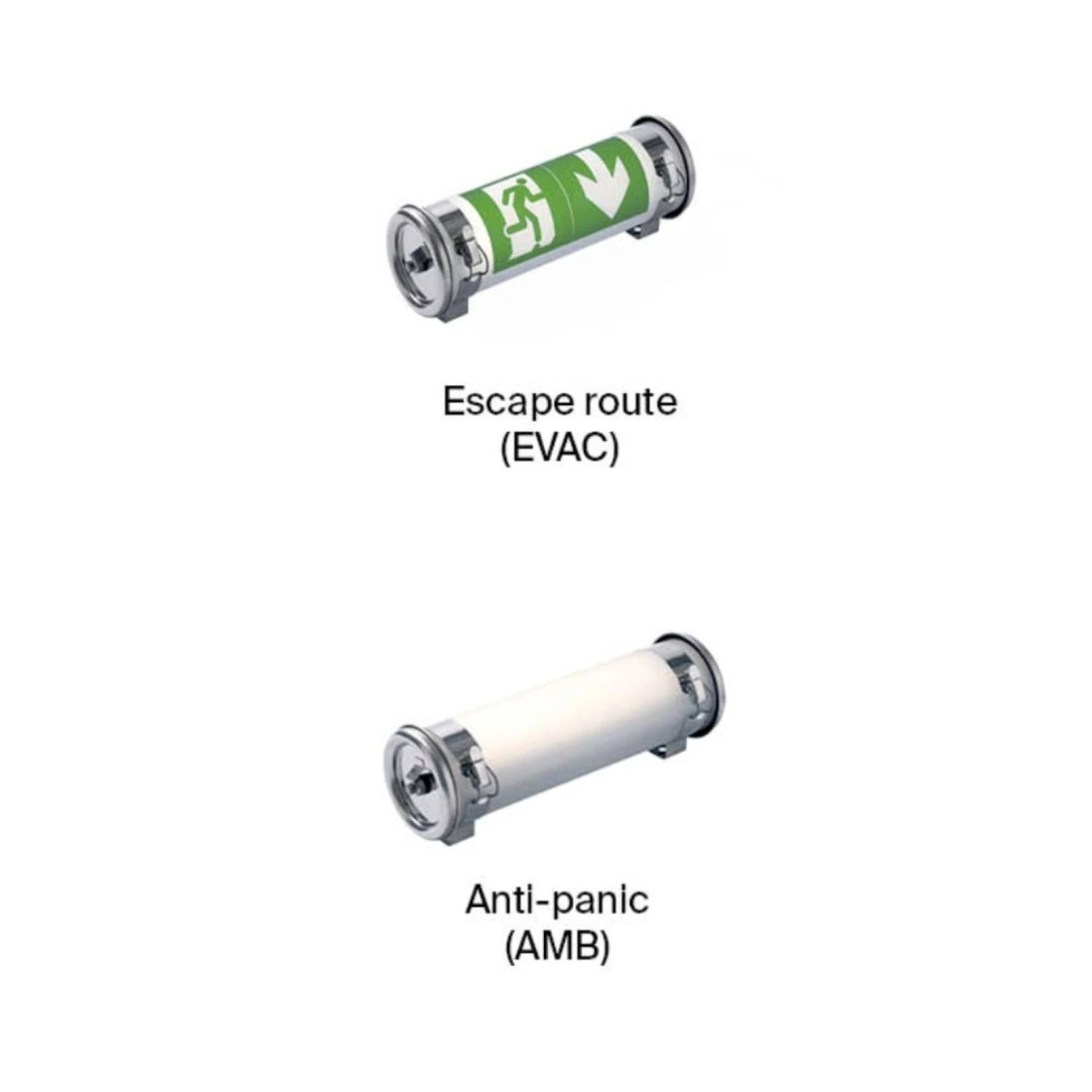

In these environments, dirt in the form of oil, lubricants or diesel is a constant concern, particularly in assembly and maintenance pits. Luminaires must be fully sealed to keep dirt out, but also humidity, particularly during cleaning. Sammode can also offer emergency lighting solutions.

Requirements

- Dust and dirt

- Need for homogeneous lighting

- Humidity and poor insulation

Recommended products

The requirements for lighting in LNG-operated (gas) bus maintenance workshops are identical to those for electric buses (humidity, dirt, homogeneous lighting). However additional risks apply, such as the explosive nature of fuel and the luminaires must therefore meet ATEX standards. Sammode can supply the lightest and easiest-to-install ATEX luminaires on the market for durable and 100% modular lighting solutions.

By installing quality lighting optimised by Sammode experts to meet the specific needs of each site, you can guarantee optimal visibility for operations and ensure the safety of personnel, but also reduce maintenance concerns in the long-term thanks to ultra-durable equipment with an 8-year warranty, not to mention a multi-decade service life.

Requirements

- Dirt and dust

- Need for homogeneous lighting

- Humidity

- ATEX environment

Recommended products

Buses are placed in outdoor storage and parking areas when not in use. Quality lighting is required in these large open outdoor areas to keep personnel safe and protect equipment. Appropriate advice is critical when it comes to making the right photometric decisions and ensuring optimal lighting quality while keeping your consumption under control.

These large open areas are lit with both tubular luminaires (local lighting) and floodlights (general lighting). Ultra-durable and reliable luminaires are essential when faced with bad weather and corrosion (humidity and UV radiation).

Requirements

- Humidity and bad weather

- Large open spaces

- UV resistance

- Difficult-to-access areas

Recommended products

- Pascal

Tube ø100 and 133 for industrial atmospheres

Electric or LNG-operated buses must be recharged or refuelled in specific areas, which are generally outdoors. These individual recharging or refuelling stations require specific lighting as buses create shadows, which must be eliminated between buses and in areas that personnel walk through.

Luminaires must offer long-term durability and full sealing compatible with outdoor use. Sammode has the necessary expertise to install ultra-durable tubular lighting (in an effectively sealed housing, no matter how extreme the conditions) which is ideal for electric recharging/gas refuelling areas (in compliance with ATEX standards for gas).

Requirements

- Humidity and bad weather

- UV resistance

- Individual lighting

- ATEX environment (gas)

Recommended products

The sealing of luminaires is even more critical at bus washing stations due to the corrosive nature of detergents and the humidity, not to mention the vibrations of the cleaning rollers which can damage the luminaire housing over time.

In this context, Sammode boasts unique experience in lighting for extreme environments based on extra-tough materials, made in France, offering total impermeability and an exceptional service life.

Requirements

- Humidity

- Chemical corrosion

- Roller vibration

Recommended products

IP68/IP69K

Durable resistance in damp environments No internal dust build-up Able to withstand high-pressure cleaning

IK10

Resistant to impacts and vibrations

Résistance aux agressions chimiques et à la corrosion

Hard-wearing materials 304L and 316L stainless steel A unique solution comprising a co-extruded polycarbonate/PMMA body

Sammode expertise

Diagnosis and recommendations

We start by analysing your operating conditions, installation requirements and other specific needs, and then recommend the most suitable solutions.

Lighting studies

Our lighting studies are designed to identify the precise quantity of luminaires and quality of the lighting solution required, while minimsing the number of light sources and energy use.

Control systems

To reduce your energy bill and improve your lighting control, our experts will suggest the management solutions best suited to your situation.

Developing special products

As both designer and manufacturer, we systematically study the best technical solutions and are able to adapt them to meet your needs.

On-site testing and support

We can manage your project from start to finish, from studies to installation, including any tests required in actual operating conditions.

Ultimate 8-year warranty

We offer an ultimate 8-year warranty for most of our products, the only such offer available on the lighting market under intensive 24/7 operating conditions.

Customer references