Cheese and dairy industry lighting

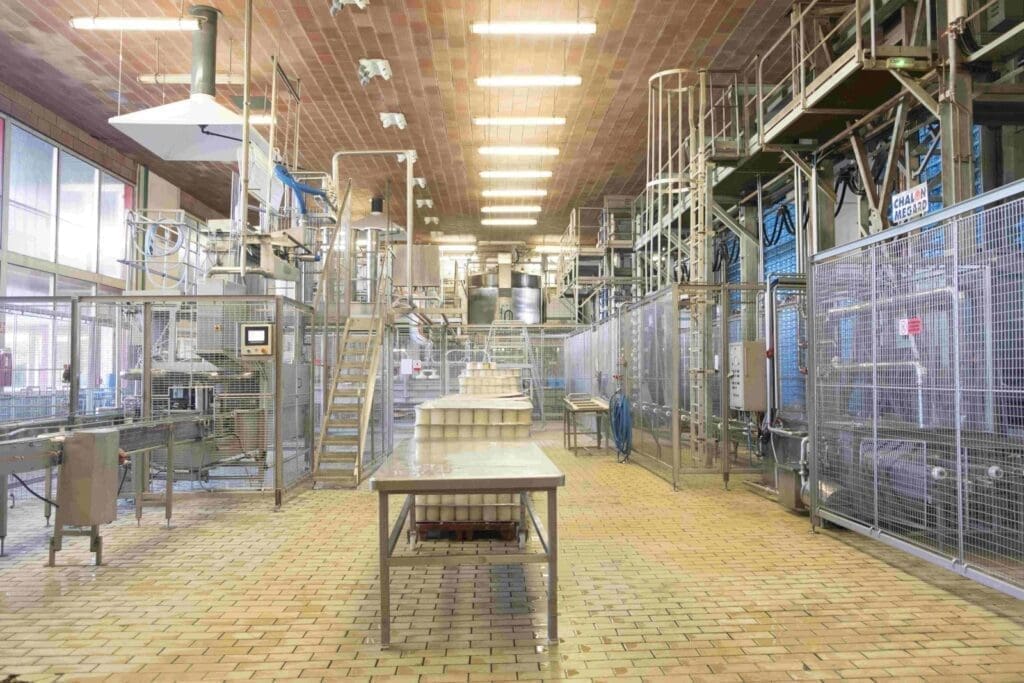

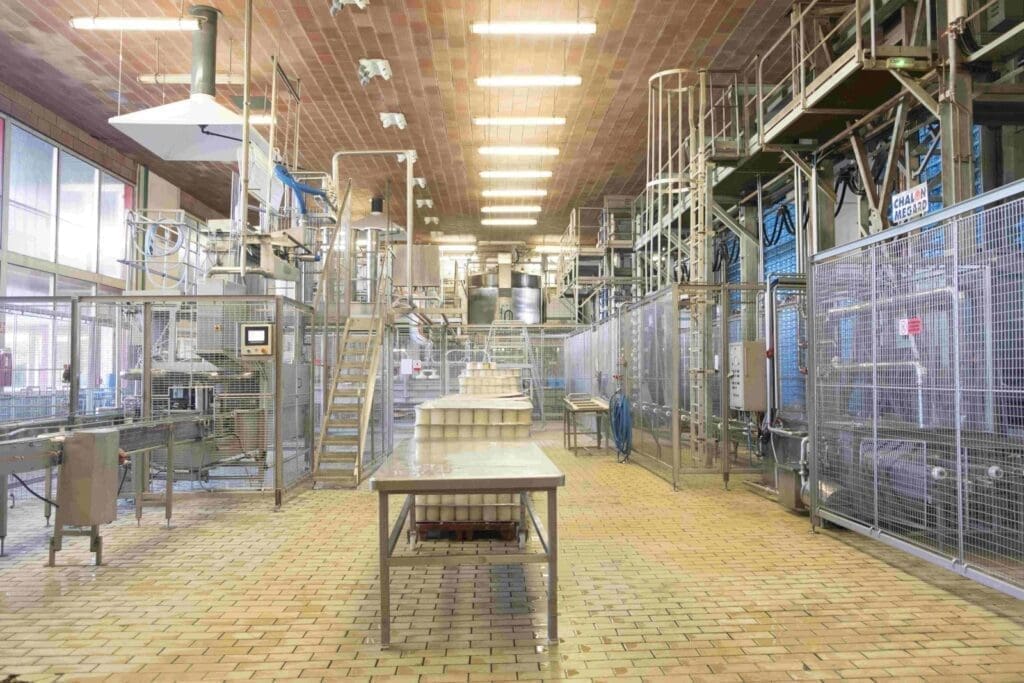

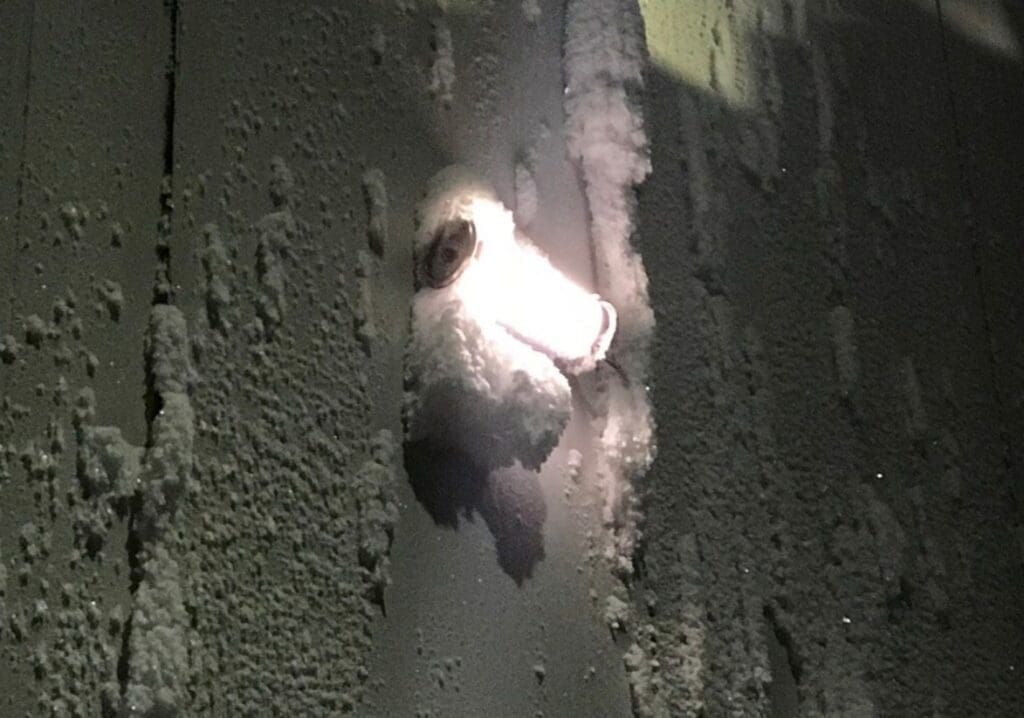

Cheese and dairy plants must meet strict health and safety standards requiring frequent high-pressure washing with corrosive detergents. Lighting at these industrial sites must be compatible with these conditions to guarantee that luminaires can be easily washed, remain fully sealed and last well into the future.

Sammode considers the mandatory switch to LED lighting from 25 August 2023 as an opportunity to install efficient, durable high-quality luminaires bringing energy savings, but also, and above all, to significantly reduce maintenance costs (particularly by temporarily outing production lines) with fully modular products covered by an 8-year warranty.

The temperature, humidity and pressure are constantly regulated in clean rooms. Milk is stored in clean rooms in the dairy industry, and the fermentation process is started here (mainly cheese and yoghurt) by adding rennet to curdle the milk. Clean rooms must be absolutely spotless.

While the clean room environment is hyper-hygienic, which requires the luminaires to be completely smooth (to avoid retaining dust and dirt in any asperities) and made of stainless steel, lactic acid is released when transforming dairy products. Lighting must be fully sealed, acid-proof and able to withstand chemical corrosion due to detergents.

Requirements

- Dust-proof

- Chemical corrosion

- Humidity

Recommended products

- Calmette

All stainless-steel recessed with rear panel opening for controlled atmosphere zones

The milk solidifies in the presence of rennet and is transformed into two separate substances: curdled milk and whey. Cheese and yoghurt are produced from curdled milk, which is diced, salted and placed in moulds. This process also occurs in strictly controlled hygienic conditions and in an environment which is frequently cleaned.

First and foremost, lighting in these areas must be good quality to avoid eye fatigue in busy areas, but the lighting units must also be completely sealed and able to withstand chemical corrosion due to detergents over the long-term. In addition, luminaires must be sturdy and able to resist the vibrations caused by machinery and conveyor belts, as well as frequent high-pressure cleaning. By limiting the need for maintenance by installing durable, easy-to-install luminaires (plug & Play, pluggable connectors), production outages are avoided.

Requirements

- Dust-proof

- Chemical corrosion

- Humidity

- High-pressure cleaning

- Detergents

Recommended products

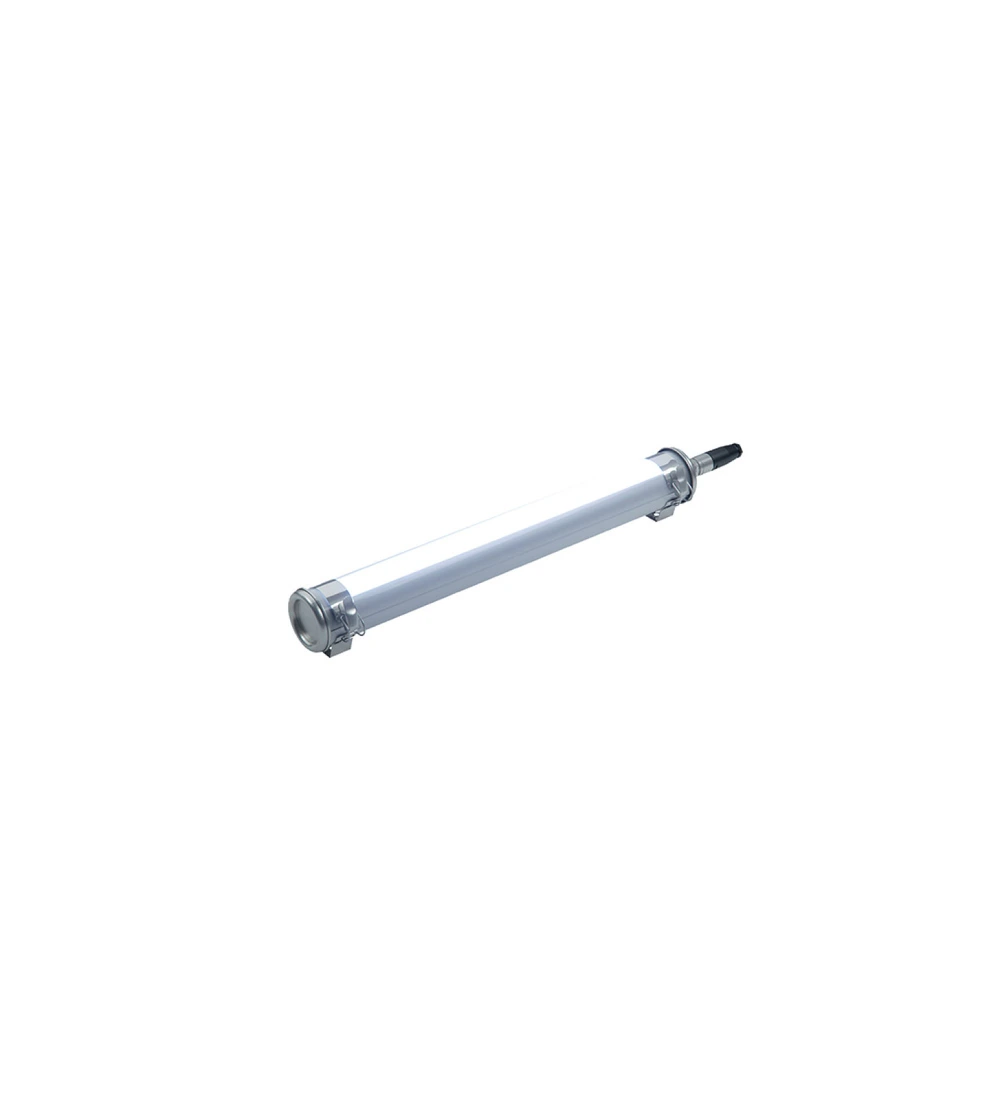

- Pascal

Tube ø100 and 133 for industrial atmospheres

The cheese is dried prior to maturing in the drying towers. 10 kg of milk are required to produce 1 kg of cheese. While most losses occur during fermentation (whey), large amounts of humidity are also lost during the drying phase as the cheese dewaters. Drying tours can also be tall and almost reach the ceiling, surrounded by temperatures of up to 75°C.

Lighting in these areas, which are frequently difficult to access, must be durable to avoid the need for maintenance operations. The lights also need to 100% modular and compatible with installation in any configuration using suitable attachments. Lighting must also remain fully sealed at all times, despite the high temperatures. Finally, specific equipment is required due to high ceilings at some sites.

Requirements

- High temperatures

- High ceilings

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

- Joule X-Heat

High temperature ø133 tube light for extreme industrial atmospheres

- Rankine X-Heat

High temperature ø70 compact tubular light fitting for confined industrial spaces

Cheese cellars and maturing zones are highly corrosive environments due to the high humidity levels (up to 90°C) and lactic acid released during the maturation process. In addition, personnel infrequently pass through these spaces, so presence detectors are recommended to save energy and extend the service life of the luminaires.

The conditions in cheese packaging areas are not as extreme as those in other production zones. However, effective lighting is required, particularly near to machines, to simplify work and guarantee visual comfort throughout the packaging process. Quality, reliable and long-lasting lighting is required for all of these reasons.

Requirements

- Extensive humidity

- Machine lighting

- Chemical corrosion

- Presence detection

Recommended products

- Pascal

Tube ø100 and 133 for industrial atmospheres

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

- Foucault

ø70 compact tubular light fitting for confined industrial spaces

While most of the whey is used directly, mainly in powdered milk and sports protein powders, some of the by-products of cheese manufacturing and other dairy works are also used to produce lactic ferments for future fermentation phases (rennet) for other dairy products.

Lactic ferment is produced in extremely cold rooms (-60°C) where specific lighting equipment must be used to protect the LED electronics from thermal shocks. Sammode luminaires are the only models available on the market to benefit from extreme cold expertise thanks to a quality fully sealed housing, including for emergency lighting.

Requirements

- Extreme cold

Recommended products

- Maxwell X-Cold

Central source or independent emergency lighting in 24V DC, permanent/non-permanent, for extreme cold environments

- Celsius X-Cold

ø70 tube light for extreme cold process or storage zones, powered off 24 VDC

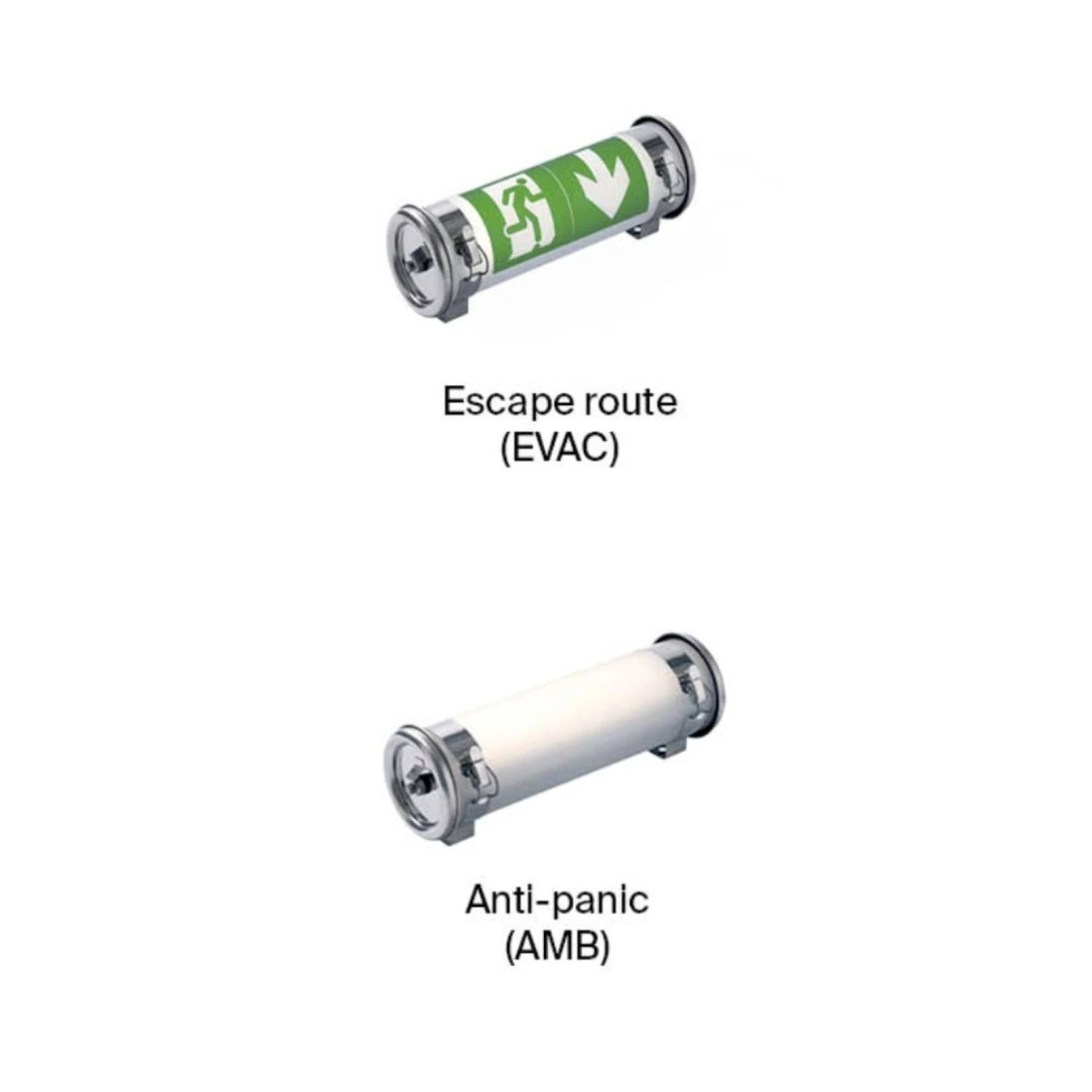

Cheese and dairy industry production sites must be equipped with emergency lighting to avoid people panicking and to simplify evacuation in the event of a power outage. Standalone emergency lighting must be installed in the different production zones.

Lactic ferment production zones have special requirements and emergency lighting designed for extremely cold conditions must be installed to guarantee the durability and sealing of the luminaires in this demanding environment. Sammode is the ultimate specialist in lighting for extremely cold zones.

Requirements

- Evacuation

Recommended products

- Maxwell

Central source or independent emergency lighting, permanent/non-permanent, for industrial environments

Ultra-robust lighting adapted to the extreme constraints of the agrifood industry

IP68/IP69K

Durable in damp environments Resistant to high-pressure cleaning

Resistance to chemical attack and corrosion

Resistant materials for use in food processing environments 304L and 316L stainless steel A unique co-extruded body solution in polycarbonate / PMMA

Compliance with IFS/BRC health and safety standards

Complete cleanability of the luminaire No risk of glass breakage Lighting quality and optical comfort

Sammode expertise

Diagnosis and recommendations

We start by analysing your operating conditions, installation requirements and other specific needs, and then recommend the most suitable solutions.

Lighting studies

Our lighting studies are designed to identify the precise quantity of luminaires and quality of the lighting solution required, while minimsing the number of light sources and energy use.

Control systems

To reduce your energy bill and improve your lighting control, our experts will suggest the management solutions best suited to your situation.

Developing special products

As both designer and manufacturer, we systematically study the best technical solutions and are able to adapt them to meet your needs.

On-site testing and support

We can manage your project from start to finish, from studies to installation, including any tests required in actual operating conditions.

Ultimate 8-year warranty

We offer an ultimate 8-year warranty for most of our products, the only such offer available on the lighting market under intensive 24/7 operating conditions.

Customer references