NPP: lighting in nuclear power plants, from the reactor building to cooling towers

Meeting reliability, safety and durability requirements is an absolute priority when managing lighting at a Nuclear Power Plant (NPP).

As a historic lighting partner of technical teams at French NPP for almost 50 years, Sammode has developed ultra-durable luminaires (ultimate 10-year warranty) designed to withstand the conditions in the different areas of nuclear power plants, which are frequently extreme and vary substantially, with their specific inherent features (chemicals, mechanical and electrical forces, sealing).

Cooling towers are the most visible parts of a nuclear power plant due to their size and the smoke plume rising into the sky. As the name indicates, they are used to cool secondary side nuclear equipment by evacuating water vapour.

For this reason, the cooling towers are constantly subjected to humidity, to runoff containing limescale and to high temperatures which increase electrical risks while rapidly depositing dirt on LED luminaires.

Requirements

- Damp and corrosive conditions

- Grime and limescale

- Extensive temperature variations

Recommended products

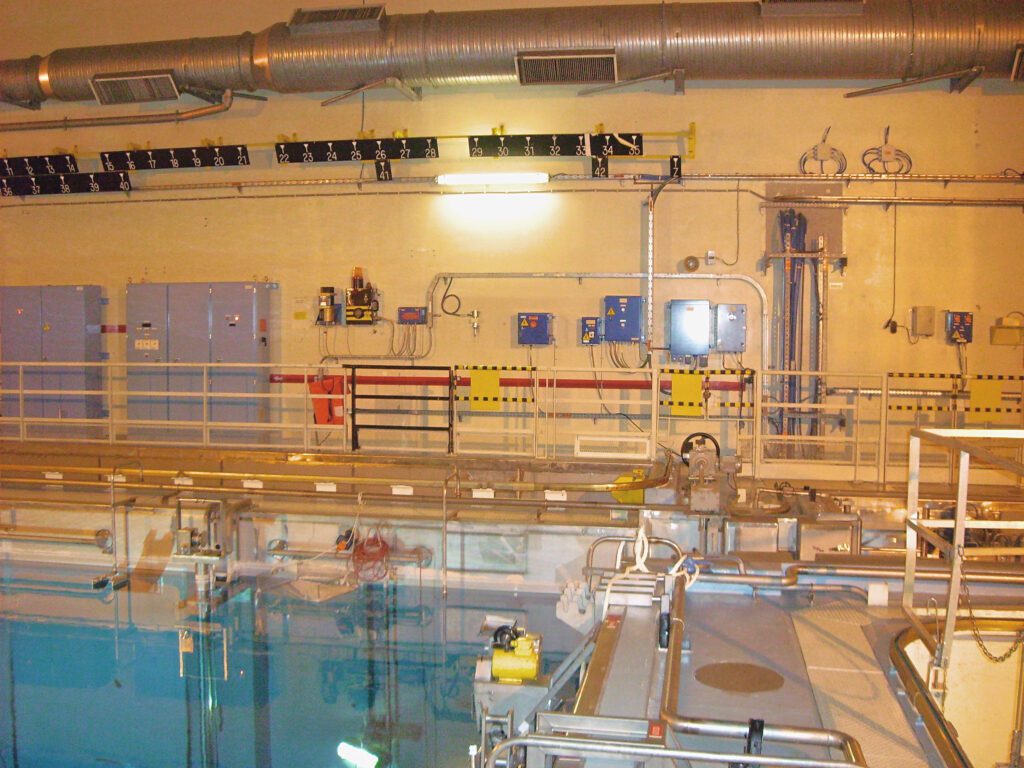

The reactor building might be less visible than the cooling towers, but it is the real core of a nuclear power plant. This is where the nuclear fission occurs, generating the energy used to produce electricity.

Reactor buildings are highly strategic and ultra-secure. The conditions inside these buildings are extremely complex, mostly (but not exclusively) due to radioactivity. Lighting equipment in these buildings must face a list of tough conditions, most notably the radiation and decontamination requirements, as well as mechanical strength, as tested during 10-year tests, and earthquake design criteria. Equipment and components must withstand:

Requirements

- Gamma radiation, decontamination

- Earthquakes (K3 type)

- Overpressure resistance during 10-year tests

- Temperature increases

Recommended products

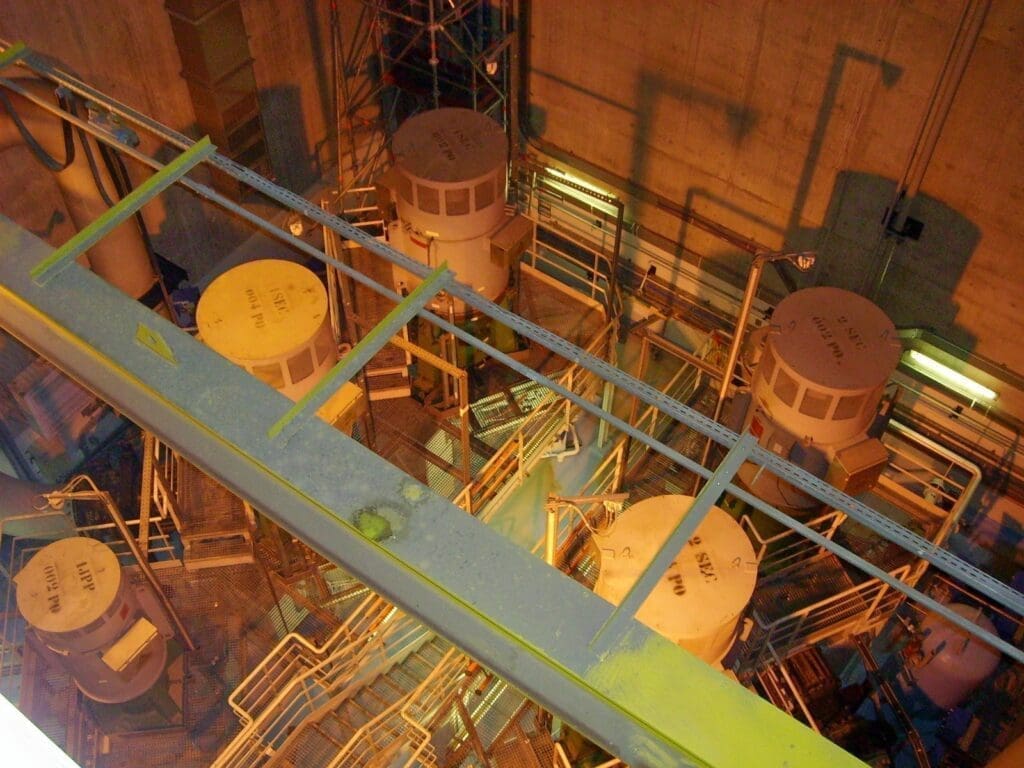

Nuclear power plant turbine halls are extremely large spaces where many operators are hard at work. That means that more light points are required here than in any other area. Turbine halls are fully fledged industrial sites in their own right, and temperatures vary significantly between the lower and upper areas, where temperatures can reach 55°C.

In addition, due to the use of large numbers of very powerful machines, LED lighting must be compatible with any electrical disturbances which could arise when large units start up, leading to voltage peaks. Finally, in the turbine hall, lighting must be able to withstand earthquakes and meet the requirements of a K3 certification, just like in other zones.

Requirements

- Ability to withstand temperature increases

- Ability to withstand power grid fluctuations

- No risk of parts projecting

Recommended products

- Joliot Industry

ø100 and ø133 class I tube light for industrial environments in nuclear power plants (excluding radioactive zones)

Electrical buildings play a vital role in nuclear power plant operations and back on to turbine halls. Electrical buildings are particularly sensitive due to the presence of electromagnetic fields and sensitive equipment. These buildings are also difficult to access.

Ultra-solid luminaires able to withstand these conditions, with an outstanding service life, must be installed. In addition, the equipment installed must not be affected by electrical or electromagnetic disturbances.

Requirements

- Avoid any potential projection of parts

- Insensitive to any types of electrical disturbances

- Limited available space and accessibility

Recommended products

Although these areas of nuclear power plants are less well known than the previous zones, they remain critical NPP components and are all generally open to outdoor areas and therefore exposed to bad weather. Consequently, these zones meet specific requirements in terms of sealing, UV resistance and dust.

The water treatment room and pumping stations are also exposed to chemical hazards due to highly corrosive acid vapours. Finally, all of these zones are difficult to access, so it is preferable to opt for equipment with the longest possible service life to reduce the need for maintenance operations.

Requirements

- Durable ultimate sealing

- Resistance to UVs and dust

- Ability to withstand power grid fluctuations

- Highly corrosive acid vapours

- Limited available space and accessibility

Recommended products

- Joliot Industry

ø100 and ø133 class I tube light for industrial environments in nuclear power plants (excluding radioactive zones)

Luminaires in these zones, where explosive risks are high, must meet ATEX standards to avoid producing sparks or excessive heat. The Sammode solutions meet all of the requirements of ATEX standards (zones 1 or 2) and are systematically certified by an independent body.

While ATEX luminaires are constructed with a heavy-duty explosion-proof housing and are therefore generally difficult to maintain or handle, Sammode has also developed a range of light-weight easy-to-maintain models. Sammode can offer a wide range of ATEX products and has developed a partnership with Marechal Electric to provide plug & play ATEX luminaires.

Requirements

- Enhanced safety features, with ATEX/iECEX certification

- Light with easy maintenance

- Wide range of luminous flux, up to 9,250 lm

Recommended products

- Sabatier Xtrem

Borosilicate glass tube ø133 for extreme or highly corrosive ATEX zone 1 atmosphere

- Jamin

Tube ø100 and 133 for industrial ATEX zone 2, 21, 22 atmospheres

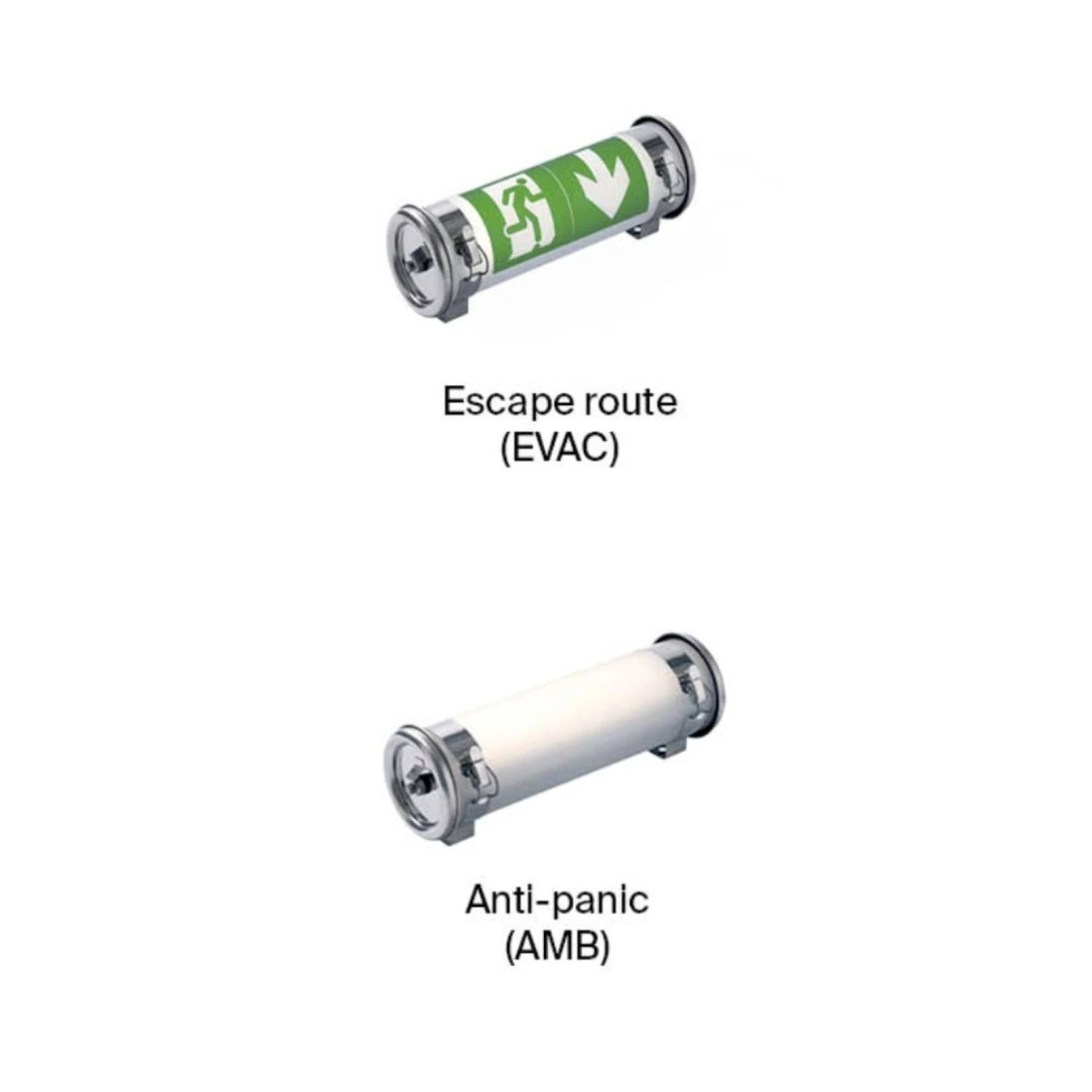

Emergency lighting plays a critical role at nuclear power plants as it guarantees the safety of personnel in the event of a power outage. Standalone emergency lighting (BAES) can play two roles: either to provide guidance during an evacuation, or to prevent panic and avoid any risk of a crowd crush. BAES must be long-lasting, reliable and solid.

In some conditions, replacement lighting models can complement BAES: these models integrate an emergency unit with lithium-ion batteries and can maintain minimal lighting levels for 3 hours to give personnel enough time to ensure safe conditions in certain areas of the nuclear power plant.

Requirements

- Easy equipment maintenance and cleaning

- Guaranteed solidity and sealing

- No risk of parts projecting

Recommended products

- Joliot Industry

ø100 and ø133 class I tube light for industrial environments in nuclear power plants (excluding radioactive zones)

Designed for extreme environments.

IK10

Resistant to IK10 impacts and vibrations K3 K3 earthquake design thanks to the unique one-piece construction of our products Temperature increases Ability to withstand temperature increases and variations IP68-69K sealing Well sealed luminaires able to keep dust, projections and water vapours out Corrosion resistance 304L and 316L stainless steel

Sammode expertise

Diagnosis and recommendations

We start by analysing your operating conditions, installation requirements and other specific needs, and then recommend the most suitable solutions.

Lighting studies

Our lighting studies are designed to identify the precise quantity of luminaires and quality of the lighting solution required, while minimising the number of light sources and energy use.

Control systems

To reduce your energy bill and improve your lighting control, our experts will suggest the management solutions best suited to your situation.

Developing special products

As both designer and manufacturer, we systematically study the best technical solutions and are able to adapt them to meet your needs.

On-site testing and support

We can manage your project from start to finish, from studies to installation, including any tests required in actual operating conditions.

Ultimate 10-year warranty

We offer an ultimate 10-year warranty for our NPP products, the only such offer available on the lighting market under intensive 24/7 operating conditions.