Steel or metal industry: lighting in extreme conditions

Lighting equipment is subjected to extreme conditions at industrial sites in the metal and steel sectors, where several types of requirements must be met to avoid shortening the service life of luminaires.

Intense heat, dust, vibrations, multi-factor corrosion, rust and sometimes explosive atmospheres (ATEX)... each metal production and transformation process brings particularly tough conditions which lighting equipment at the site must withstand. To avoid wasting time or capital in maintenance and replacing parts, it is essential to install solid and durable luminaires suitable for each area and the specific conditions in each zone.

Raw materials are routed to and stored in these areas prior to crushing and sorting. The raw material reception and agglomeration area requires special consideration due to the scale and permanent nature of the vibrations produced by the large machines used to transport, extract and sort materials (railways, ships, excavators, giant hoppers, etc.). All equipment installed in this area must be compatible with the substantial amount of dust due to the handling of large volumes of materials.

We recommend that you install CUGNOT Xtrem tubular luminaires for local lighting and SILL 48 and SILL 176 floodlights for remote lighting to cover these conditions. In addition to the high levels of sealing offered by all Sammode products, these luminaires are designed in one-piece housings to prevent vibrations from propagating through the luminaire. The electronic components are mechanically reinforced to absorb even the most intense vibrations.

Requirements

- Intense and constant vibrations

- Dust and dirt

- Exposure to UVs and bad weather

- Exposure to coastal corrosion

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

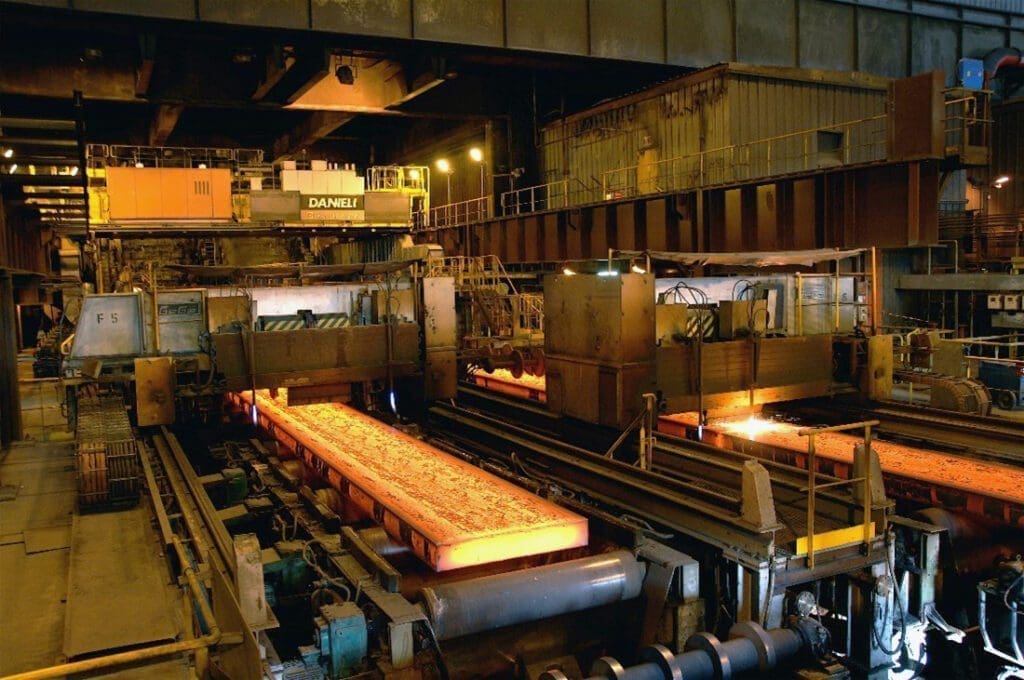

Extreme heat prevails at coking plants, blast furnaces and steelworks. Materials are melted and transformed at these sites. In addition to the technical challenge inherent in lighting located in an area with such high temperatures, it is also essential to consider the potential chemical damage caused by corrosive particles emitted by the materials and the transformation processes, not forgetting the explosive atmospheres (ATEX). The air in these areas is often contaminated with flammable particles (dust, gas); the electrical equipment used must therefore be totally reliable for obvious safety reasons.

We recommend that you adapt your lighting equipment in these sensitive areas depending on the distance between luminaires and risks. The JOULE X-Heat luminaire or the LESLIE X-Heat model (with its corrosion-proof glass diffuser) are ideal for such environments; or we could suggest the BOYLE Xtrem or SABATIER Xtrem tubular luminaires for explosive atmospheres (ATEX).

Requirements

- Extreme heat

- Multi-factor corrosion

- Explosive atmosphere (ATEX)

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

- Joule X-Heat

High temperature ø133 tube light for extreme industrial atmospheres

- Leslie X-Heat

High temperature borosilicate glass tube ø133 for highly corrosive atmospheres

- Pauli HT200 X-Heat

Very high temperature ø133 incandescent tube light

- Boyle Xtrem

Borosilicate glass tube ø100 and ø133 for extreme or highly corrosive ATEX zone 2, 21 and 22 atmospheres

- Sabatier Xtrem

Borosilicate glass tube ø133 for extreme or highly corrosive ATEX zone 1 atmosphere

The metal is heated, transformed, cooled, cut and treated with highly corrosive chemicals in this zone. Levels of corrosive vapours are high due to the nearby continuous casting and hot rolling belts.

Electrical disturbance must also be considered in this area due to the use of power machinery, requiring lighting equipment with reinforced electronics.

CUGNOT Xtrem, JOULE X-Heat and LESLIE X-Heat tubular luminaires, and SILL series 48 floodlights, with their reinforced surface treatment to prevent corrosion, are ideal for these requirements, guaranteeing long-lasting and reliable lighting for industrial sites.

Requirements

- Corrosion

- Electrical disturbances

- Heat

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

- Joule X-Heat

High temperature ø133 tube light for extreme industrial atmospheres

- Leslie X-Heat

High temperature borosilicate glass tube ø133 for highly corrosive atmospheres

It is a legal imperative and safety requirement to install emergency lighting in the form of standalone luminaires (BAES), luminaires for central sources (LSC) or replacement lighting. This type of lighting guarantees that production areas, corridors and emergency exits at the industrial site are visible at all times if the power grid fails. For this reason, such lighting must comply with the applicable standards, be compatible with the environment in which it is installed and clearly be powered by a source other than the central power grid for the industrial site.

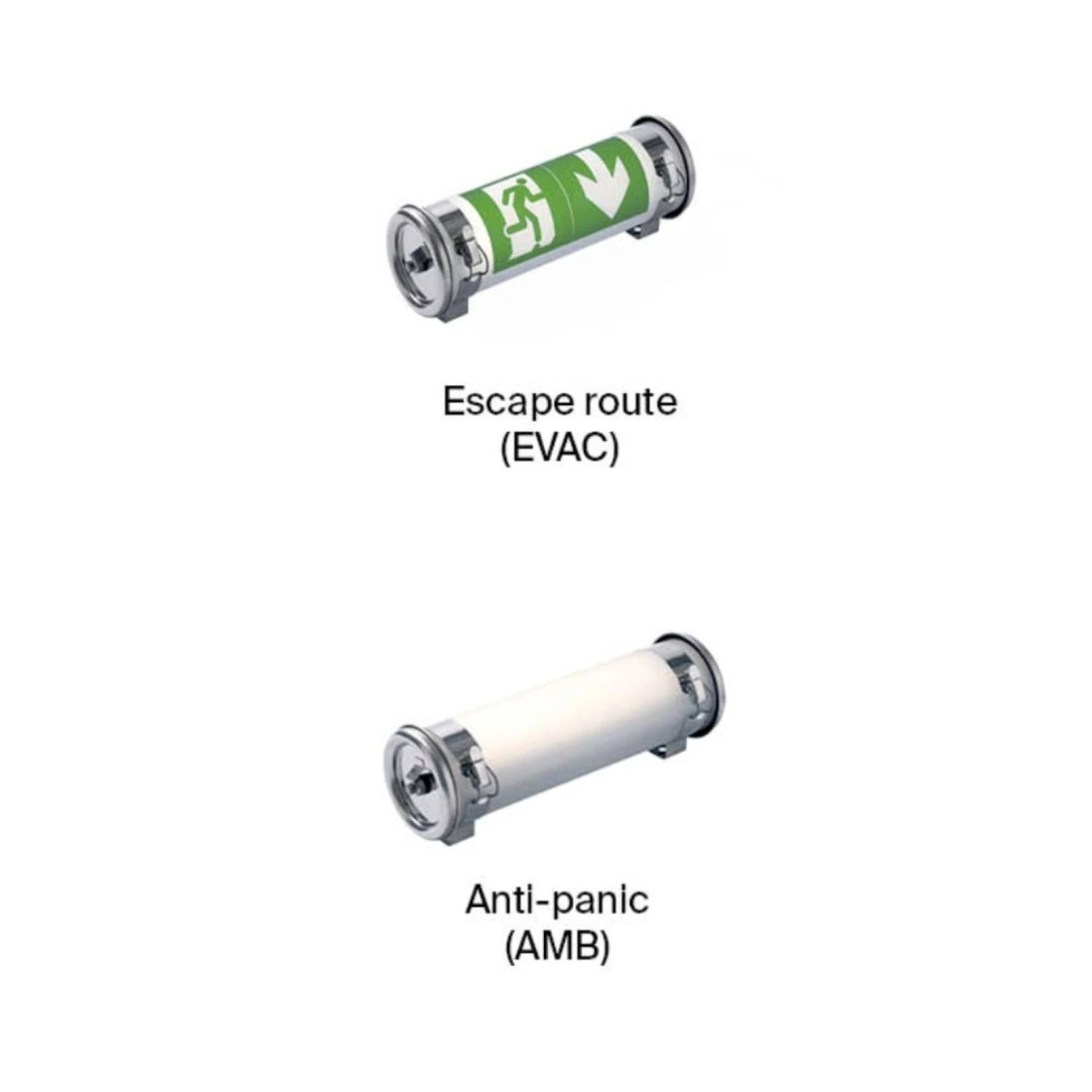

The COULOMB and MAXWELL emergency luminaires offer the same guaranteed solidity and durability as our other industrial systems, largely thanks to the quality of the Sammode housing, renowned for its high-level sealing and sturdy composition. These luminaires are equipped with batteries (BAES) or a connection to a secondary emergency power source (LSC), guaranteeing evacuation (EVAC) or ambient (AMB) lighting if the main grid fails.

In an ATEX zone, the BOYLE luminaire can also be used as replacement lighting as an option (1-hour Lithium-ion batteries) to complete important works if the grid fails.

Requirements

- Powered by a separate source to the main power grid

- Suitable for the environmental conditions in the zone

- Compliant with EN 60 598-2-22 and NF AEAS certified (France)

- Explosive atmospheres (ATEX)

Recommended products

- Boyle Xtrem

Borosilicate glass tube ø100 and ø133 for extreme or highly corrosive ATEX zone 2, 21 and 22 atmospheres

Large outdoor areas (car parks, stair cases, gangways, areas around buildings, etc.) must be lit to allow personnel to access and move around the industrial site safely. Such lighting is frequently installed in places that are particularly difficult to reach and often at height. To keep a cap on maintenance costs and optimise operating expenses, industrial sites must make sure that they install highly efficient, reliable and durable lighting equipment. It is also essential to ensure that the solutions installed are powerful enough for the area to be lit, with suitable photometry, providing adequate lighting levels spread evenly over the area to avoid shadows.

We recommend installing SILL 176 and 177 floodlights on the different masts, brackets and pylons, and using CUGNOT Xtrem tubular luminaires for local lighting (walkways, staircases, gangways, and around buildings at ground level). These two ranges combine solid electronics with high-performance anti-corrosion properties.

Requirements

- Height

- Complicated access

- Efficient lighting levels and photometry

- Exposure to UVs and bad weather

- Exposure to coastal corrosion

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

Designed for extreme environments.

IK10 – Vibrations and impacts

Able to withstand intensive vibrations and impacts (IEC 60068-2-6).

UV

Co-extruded polycarbonate/methacrylate body able to withstand acids and UV radiation over the test of time.

Able to withstand high temperatures

Up to +200°C with a laminated glass body. LED lighting solutions compatible with temperatures up to +70°C. A housing system able to absorb the effects of temperature variations.

Sammode expertise

Diagnosis and recommendations

We start by analysing your operating conditions, installation requirements and other specific needs, and then recommend the most suitable solutions.

Lighting studies

Our lighting studies are designed to identify the precise quantity of luminaires and quality of the lighting solution required, while minimsing the number of light sources and energy use.

Control systems

To reduce your energy bill and improve your lighting control, our experts will suggest the management solutions best suited to your situation.

Developing special products

As both designer and manufacturer, we systematically study the best technical solutions and are able to adapt them to meet your needs.

On-site testing and support

We can manage your project from start to finish, from studies to installation, including any tests required in actual operating conditions.

Ultimate 8-year warranty

We offer an ultimate 8-year warranty for most of our products, the only such offer available on the lighting market under intensive 24/7 operating conditions.

Customer references