Sugar industry: lighting for sugar refineries, washing areas and alcohol transformation areas

Several challenges must be faced for lighting at sugar refineries, throughout the refinery process. When raw materials are delivered, we are talking about an extremely dirty, outdoor industrial farming environment. As the processing moves on, we turn to a food industry environment subject to strict health and safety standards, and then an ATEX environment during distillation.

In this extremely energy-intensive environment, suitably designed robust luminaires are essential, as well as support from experts to assist with a lighting configuration able to meet all needs – particularly with a switch to LED luminaires. For over half a century now, Sammode’s teams have been supplying a wide range of lighting solutions designed for all industrial situations, plus an 8-year warranty covering extreme conditions.

When raw materials (sugar cane or sugar beet) are unloaded from trucks, they are transported to the washing area on conveyor belts. This heavy-duty industrial process is extremely dirty with splashes of sludge and the vibrations inherent in this process.

Luminaires in these outdoor areas must withstand various types of constraint. Large surface areas must be lit up (including outdoor areas such as unloading and storage areas and car parks) with lighting equipment that is frequently hard to access, and installed in corrosive conditions due to bad weather and UV radiation. However, it is also essential to consider conveyor belt vibrations, which require LED luminaires with specific ultra-sturdy electronics, and the risk of becoming coated in earth or sludge, which demands maximum durability for the sealing.

Requirements

- Dust build-up

- Solid grime

- Vibrations

- Corrosion

- UVs and bad weather

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

- Fresnel

Tube ø133 for high-ceilinged industrial atmospheres

Once the raw materials have been cleaned, they are cut up into strips. These strips are soaked in a flow of warm water, which is gradually infused with sugar. This diffusion process, which precedes liming, a filter process using lime slurry, removes all impurities from the sweet juice obtained.

The industrial conditions found in washing areas (dirt and vibrations) are also present in these areas; however, additional factors such as temperature and high-pressure cleaning for both machines and premises must be considered, so well-sealed, robust luminaires are necessary. While Sammode’s range is particularly long-lasting, we also guarantee the availability of spare parts well into the future by proposing modular systems that can be fully dismantled and repaired at the site.

Requirements

- Solid grime

- Vibrations

- High-pressure cleaning

- Temperature

Recommended products

- Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

The sweet juice is then heated to a high temperature in boilers to allow the water to evaporate, increasing the sucrose concentration from 15% to 70%. Fine icing sugar crystals are then added to cause some of the juice to crystallise. The mass of sugar and remaining juice are then centrifuged to separate both elements and obtain sugar. This sugar is then dried using hot air dryers.

These drying areas must meet the applicable health and safety standards for the food industry, and lighting must withstand both the high temperatures prevailing for the different sugar refining processes and the potential chemical damage caused by cleaning products, not forgetting the ability to support the high-pressure cleaning of machines and premises. For all of these reasons, robust luminaires able to withstand high temperatures must be installed.

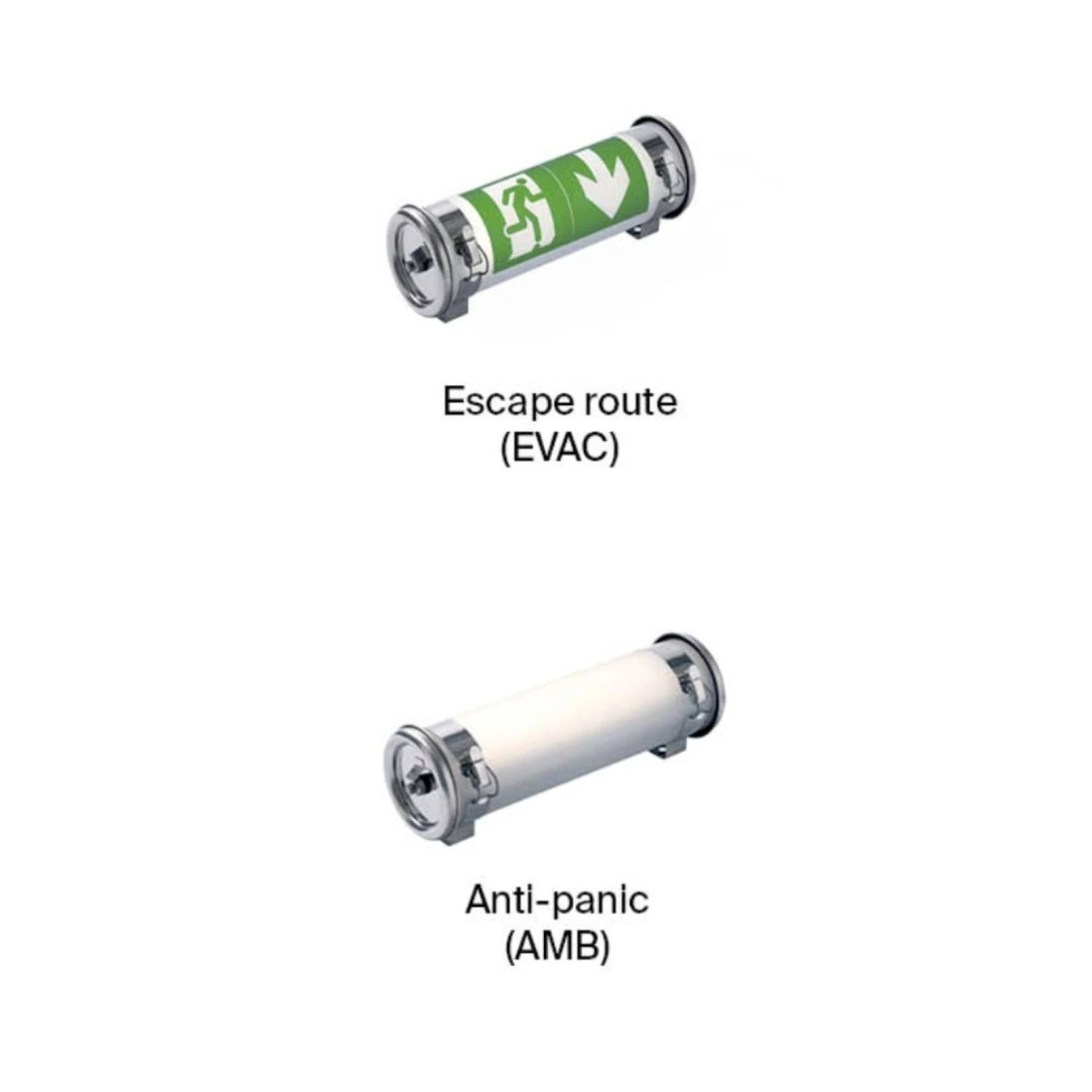

In addition, as is the case in any area at a sugar refinery, suitable emergency lighting must be fitted.

Requirements

- High temperature

- High-pressure cleaning

- Chemical damage

Recommended products

- Joule X-Heat

High temperature ø133 tube light for extreme industrial atmospheres

- Coulomb

Central source or independent emergency lighting

- Maxwell

Central source or independent emergency lighting, permanent/non-permanent, for industrial environments

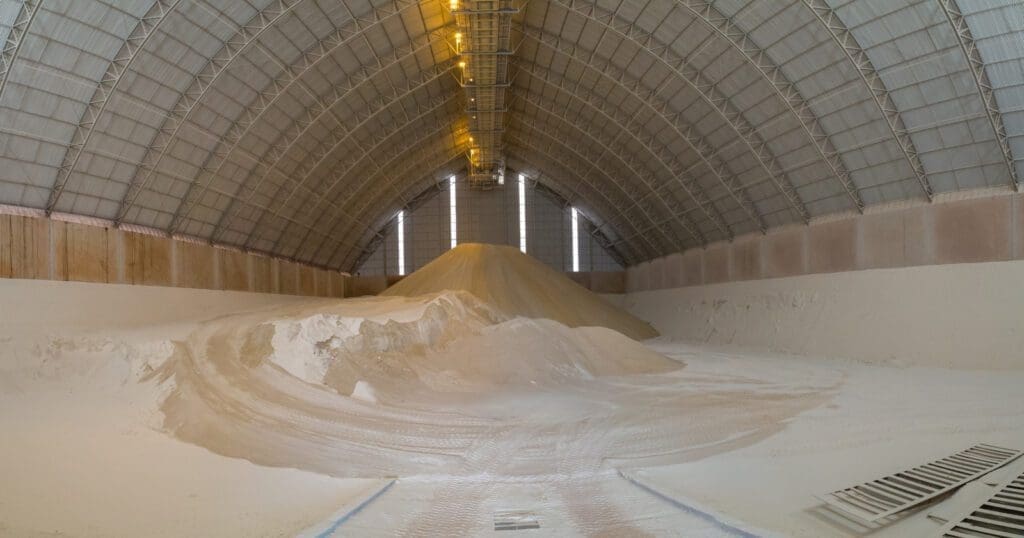

Once the sugar powder has cooled, it is stored in silos. Once the sugar has fully stabilised, it is packaged as either cubes or crystals, or sent out directly in bulk form. These storage areas bring new industrial requirements as this environment is considered as potentially explosive under ATEX category 21 or 22 (explosive dust).

Luminaires in these areas must therefore satisfy these ATEX standards. High temperatures (45/50°C) also form under the ceilings in these areas, requiring suitable products, which must also be particularly reliable as any electrical works in an explosive atmosphere imply significant risks and extra costs. To allow for intervention in record time in these complex areas, Sammode has partnered with Marechal Electric to provide robust and easy-to-install ATEX-certified Plug & Play cables for its luminaires.

Requirements

- Explosive atmospheres

- Dust zone 21,22

Recommended products

- Boyle Xtrem

Borosilicate glass tube ø100 and ø133 for extreme or highly corrosive ATEX zone 2, 21 and 22 atmospheres

- Fumat

Tube ø133 for high-ceilinged ATEX zone 2,21,22 atmospheres

The molasses (sweet juice containing impurities, separated from the sugar during centrifugation) and sweet water are not retained as part of the final product, but are however used. These by-products are distilled to produce alcohol in the large tanks so typical of sugar refineries, particularly in northern France.

These explosive atmospheres contain gas from alcohol vapours, rather than the dust usually found in silos. On this basis, the lighting equipment must comply with ATEX zone 1 and 2 standards depending on the risks faced, and must withstand the high temperatures (up to 50°C) frequently found in this type of process. Sammode offers a “replacement lighting” option for its ATEX zone 2 ranges to ensure optimal safety, courtesy of the built-in Lithium-ion batteries, providing a minimal lighting level for 1 hour if the main power grid fails.

Requirements

- Explosive atmospheres

- Gas zone 1, 2

Recommended products

- Sabatier Xtrem

Borosilicate glass tube ø133 for extreme or highly corrosive ATEX zone 1 atmosphere

- Boyle Xtrem

Borosilicate glass tube ø100 and ø133 for extreme or highly corrosive ATEX zone 2, 21 and 22 atmospheres

Designed for extreme environments

Compliance with food industry standards

All our products contribute to the IFS or BRC and HACCP compliance of your food processing site, meeting the requirements of these standards in terms of lighting.

IP68/69K

Durable ultimate sealing. No internal dust build-up. Able to withstand high-pressure cleaning.

Sammode expertise

Diagnosis and recommendations

We start by analysing your operating conditions, installation requirements and other specific needs, and then recommend the most suitable solutions.

Lighting studies

Our lighting studies are designed to identify the precise quantity of luminaires and quality of the lighting solution required, while minimsing the number of light sources and energy use.

Control systems

To reduce your energy bill and improve your lighting control, our experts will suggest the management solutions best suited to your situation.

Developing special products

As both designer and manufacturer, we systematically study the best technical solutions and are able to adapt them to meet your needs.

On-site testing and support

We can manage your project from start to finish, from studies to installation, including any tests required in actual operating conditions.

Ultimate 8-year warranty

We offer an ultimate 8-year warranty for most of our products, the only such offer available on the lighting market under intensive 24/7 operating conditions.

Customer references