Rankine X-Heat

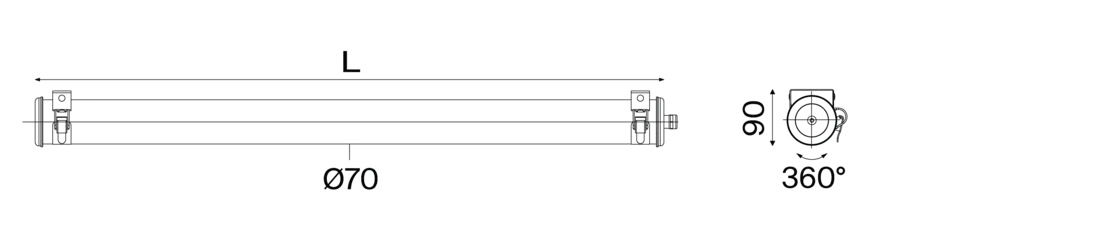

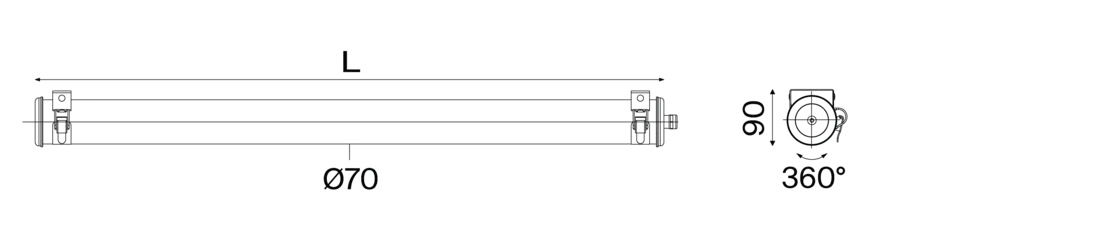

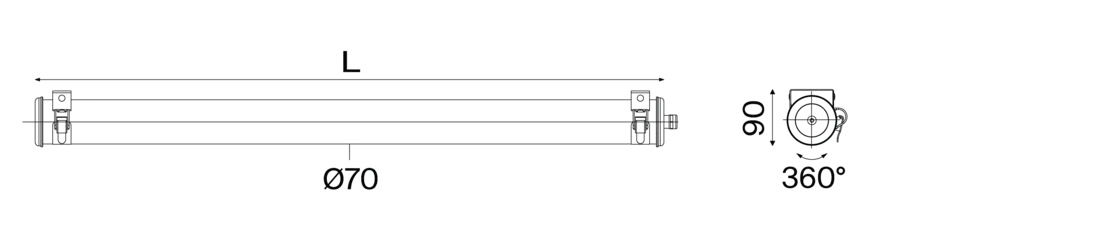

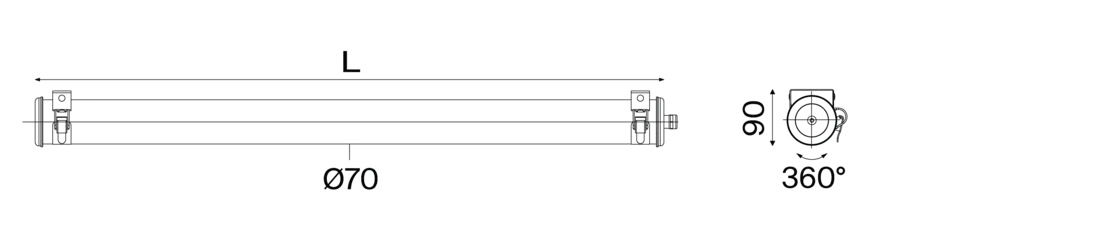

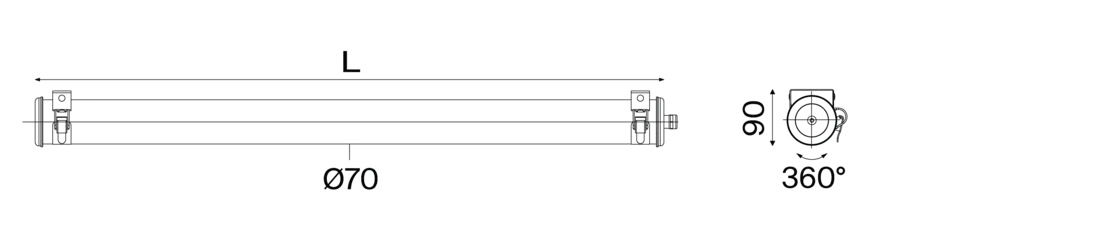

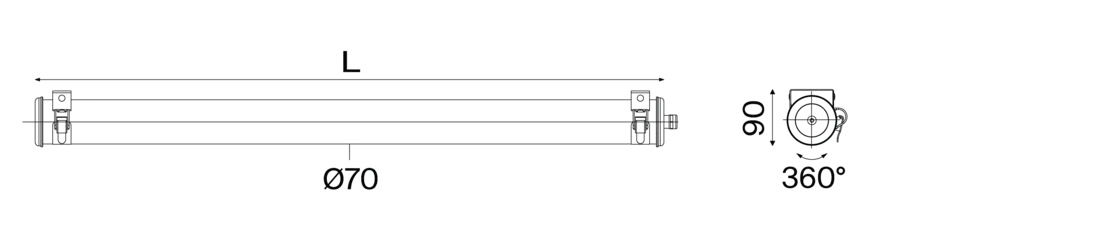

High temperature ø70 compact tubular light fitting for confined industrial spaces

A smart and practical tubular luminaire to optimise visibility in the tightest corners

The Foucault tubular luminaire is a durable and efficient lighting choice thanks to its optimal sealing and the use of ultra-durable LED components and materials, drawing on our extensive lighting experience in industrial environments. With an extensive choice of lengths and light outputs, it is suited to any kind of space, including the most confined areas, courtesy of the compact versions.

Corrosive substances, acid vapours

Oils & hydrocarbons

Saline atmosphere, sea spray

UV radiation and bad weather

Dust and humidity

Washing with a high-pressure jet

Health and safety requirements according to IFS, BRC and HACCP texts

Permanent use at temperatures of up to 40°C

Extreme variation in temperature

Repeated turning on and off

Heavy mechanical impacts

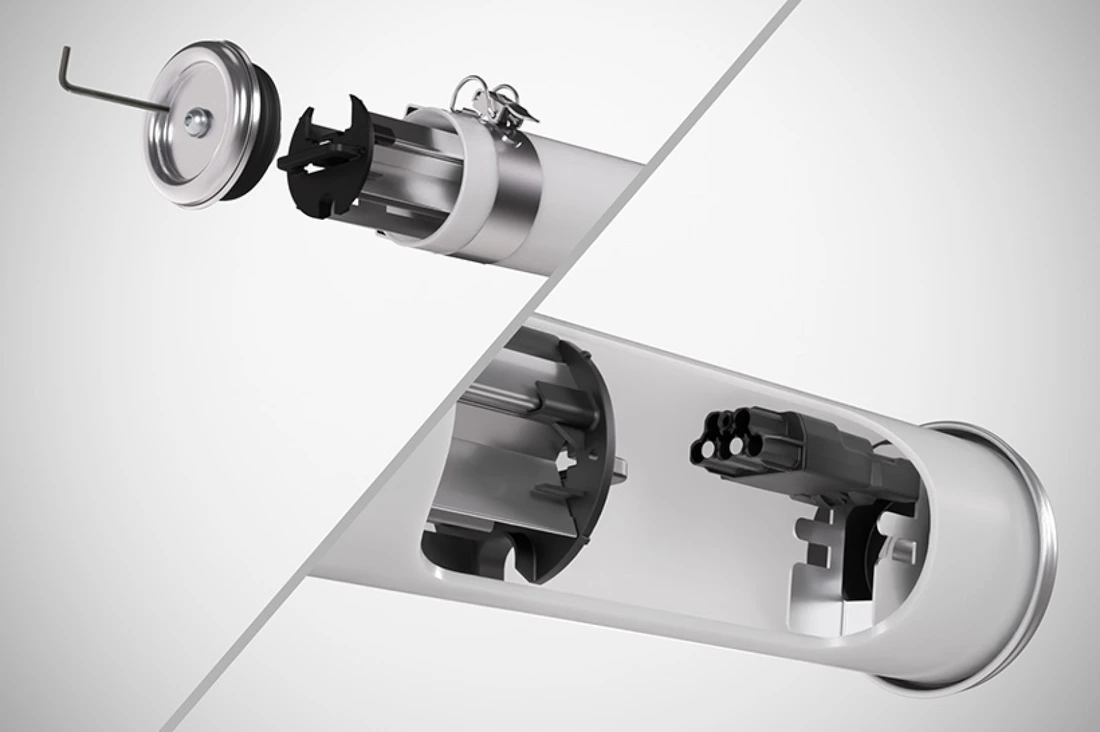

Intense and repetitive vibrations

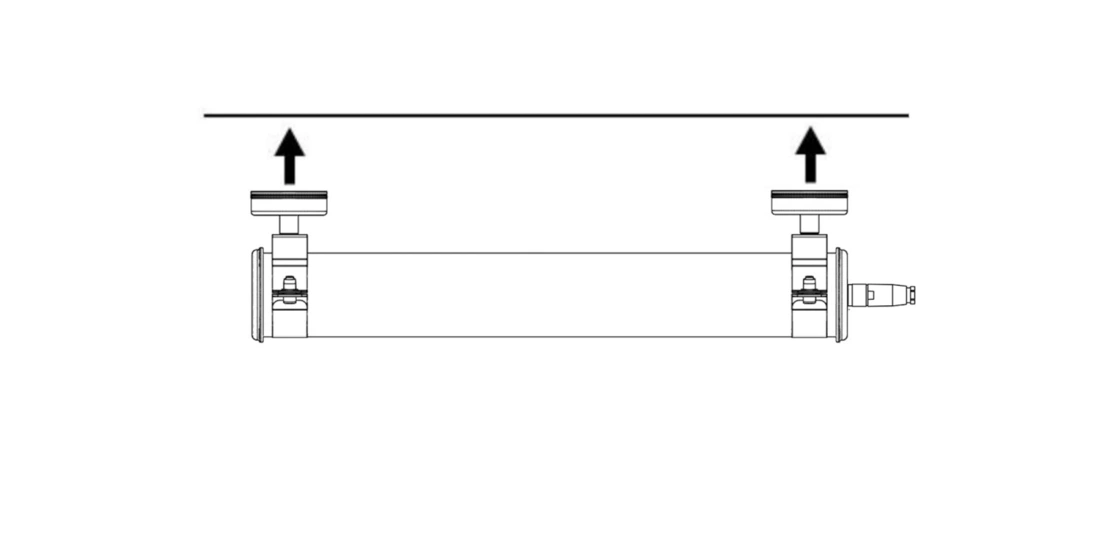

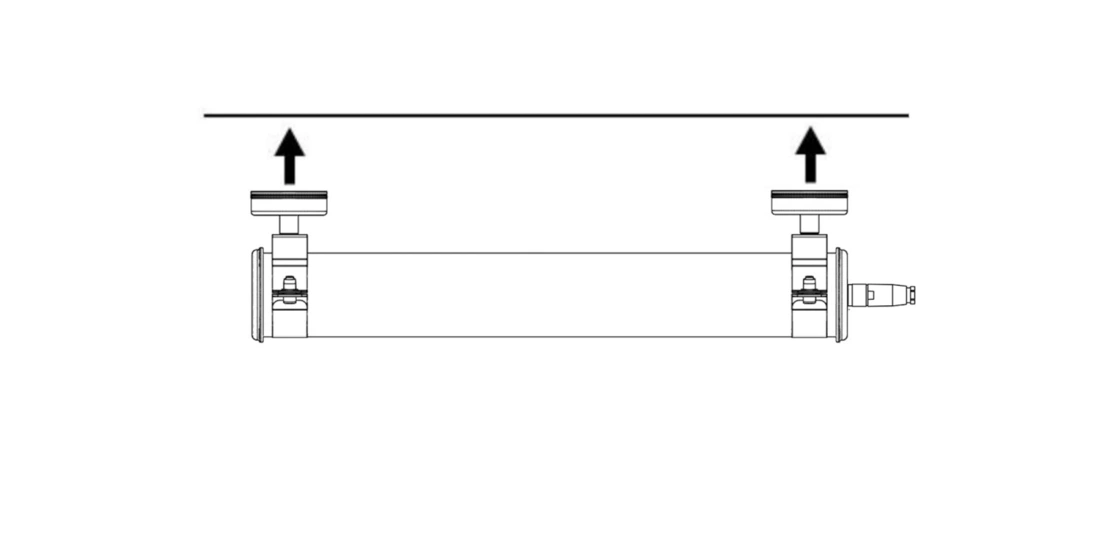

The most compact Sammode model is also our most ingenious luminaire, thanks to the option to perform maintenance without having to touch the cable, by extracting the gear tray on the opposite site to the power unit. An innovative device, with an automatic electrical connection at closure, making the luminaire easy to repair and upgrade.

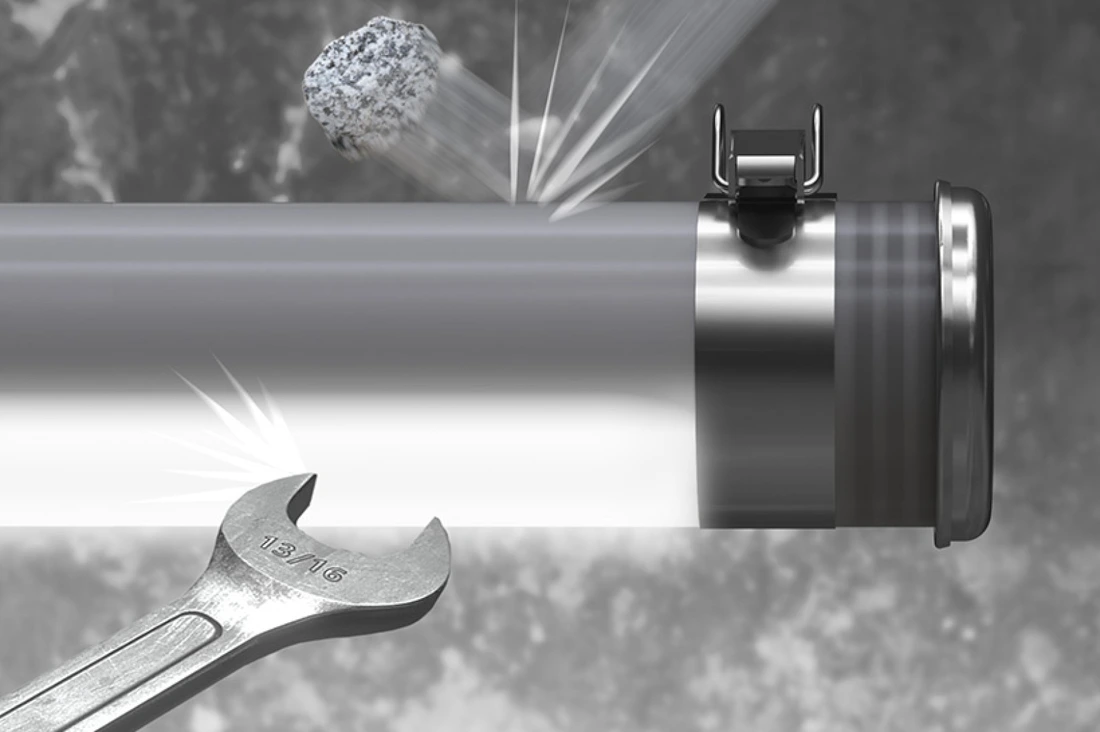

The co-extruded PMMA and polycarbonate tubular housing is sealed by tightening the nut under the cable gland. With this technique, the gasket expands evenly, guaranteeing absolute sealing for any type of humidity (IP68, IP69K), even if temperatures vary significantly.

Its reinforced stainless steel end-caps and fixing straps, combined with its composite diffuser protected from corrosive substances by co-extruded PMMA, ensure exceptional resistance against the detergents used in a food environment, and the acid vapours, oils and solvents used in industry.

Sammode has everything covered! A light but solid luminaire, the FOUCAULT model offers several Plug & Play installation options, with straight or angled pluggable connectors. As the icing on the cake, a magnetic fastening kit can be fitted on the fixing straps, to temporarily secure the luminaire to metal walls (320 N per magnet).

Equipment installed in narrow industrial spaces must be reliable and robust, which is why Sammode selected homogeneous materials with unfailing mechanical strength and no mating surfaces. The result: an ultra-durable, impact- and vibration-proof IK10 housing.

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Valid even for 24/7 use at the maximum operating temperature for the product. 8-year warranty you will not find anywhere else on the market, reflecting our unfailing commitment to our customers!

Unlike the disposable world we live in, Sammode lights are designed as modular systems. New technology can be integrated in existing fixtures: simply replace the outdated parts!

|    |

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|---|---|---|---|---|---|---|---|---|

| 800 | 430 | FOU70 450 800-840 POME 113LN | 34035301 | 8 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 1200 | 575 | FOU70 575 1200-840 POME 113LN | 34035302 | 10 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 1600 | 715 | FOU70 700 1600-840 POME 113LN | 34035303 | 13 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 2400 | 995 | FOU70 1000 2400-840 POME 113LN | 34035304 | 20 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 3200 | 1275 | FOU70 1300 3200-840 POME 113LN | 34035305 | 25 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 4000 | 1560 | FOU70 1600 4000-840 POME 113LN | 34035318 | 31 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 4800 | 1840 | FOU70 1850 4800-840 POME 113LN | 34035319 | 36 | Data sheet | Plan | STEP DS | .TXT | Download all |

|    |

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|---|---|---|---|---|---|---|---|---|

| 800 | 430 | FOU70 450 800-840 CL2 POME 113LN | 34035320 | 8 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 1200 | 575 | FOU70 575 1200-840 CL2 POME 113LN | 34035321 | 10 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 1600 | 715 | FOU70 700 1600-840 CL2 POME 113LN | 34035322 | 13 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 2400 | 995 | FOU70 1000 2400-840 CL2 POME 113LN | 34035323 | 20 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 3200 | 1275 | FOU70 1300 3200-840 CL2 POME 113LN | 34035324 | 25 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 4000 | 1560 | FOU70 1600 4000-840 CL2 POME 113LN | 34035325 | 31 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 4800 | 1840 | FOU70 1850 4800-840 CL2 POME 113LN | 34035326 | 36 | Data sheet | Plan | STEP DS | .TXT | Download all |

| Coextruded polycarbonate/ PMMA housing with high chemical resistance | POME |

| Polycarbonate housing | PO |

| End caps & fixing straps 304L stainless steel | - |

| End caps & fixing straps 316L stainless steel | MR |

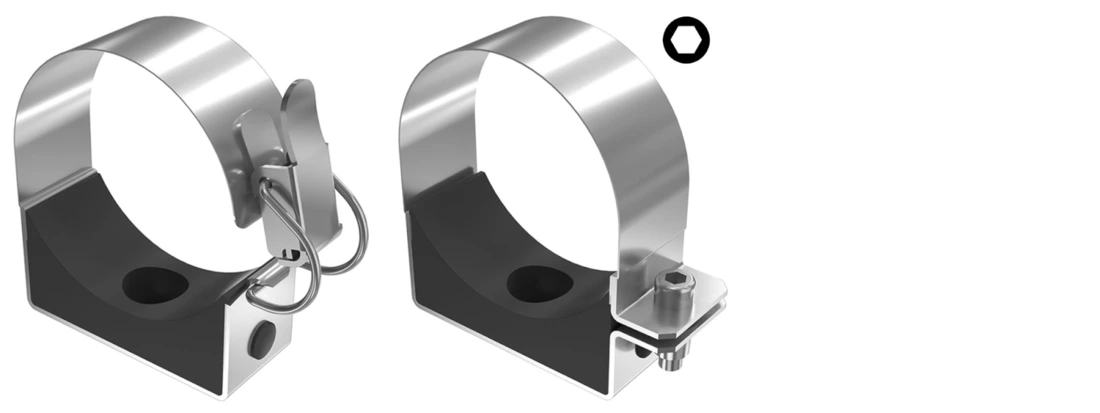

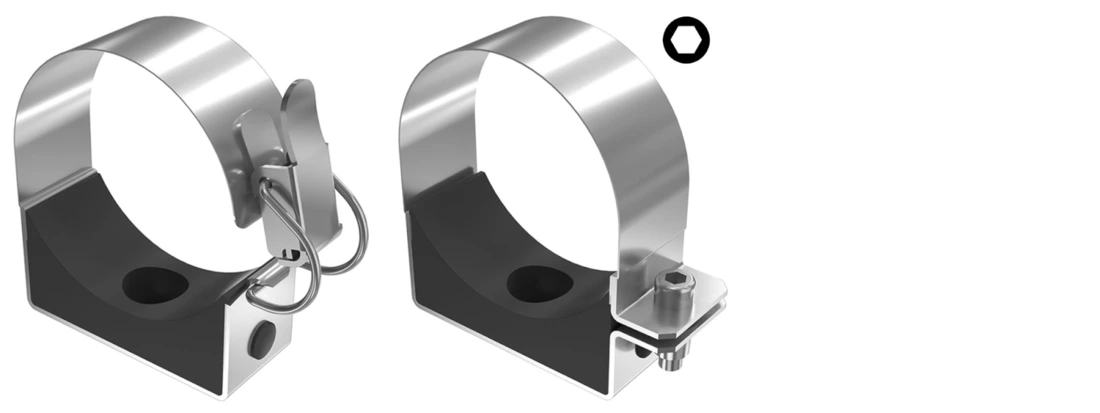

| Fixing straps | - |

| Fixing straps with HSHC screw | BAV |

| IP68/69K quick-lock plug with threaded ring (capacity: Ø8 to 10 mm) | PS2/PS3 |

| IP65 angular socket for screw locking (capacity: Ø6 to 13 mm) | PB2/PB3 |

| 3000K | 830 |

| 4000K | 840 |

| Electronic gear unit for DALI 2 dimming | RD |

| Switch-off warning function (for sensor/timer) | RC |

| Built-in presence sensor (length increased by 85mm) | SI |

| Class I | - |

| Class II | CL2 |

| Through wiring (except 450mm) | TR |

| Magnetic fixings kit for 2 fixing straps (320N per magnet) PU45080 |

| 2 x 20 cm 304L stainless steel extensions PU44277 | |

| 2 x 20 cm 316L stainless steel extensions PU47378 | |

| 2 x 5 cm 304L stainless steel extensions PU44278 | |

| 2 x 5 cm 316L stainless steel extensions PU45880 |

| Stripped free end CAB0080 | |

| Wieland® plug IP68/IP69K (capacity : Ø10-14mm) CAB0095 | |

| Wieland® plug and Y spliter for loop-in/out CAB0145 |

| Light source |

|

| Optics |

|

| Heat management |

|

| Control gear |

|

| Supply voltage |

|

| Electrical class |

|

| Operating temperature |

|

| Connection |

|

| Mounting |

|

| LED engine maintenance |

|

| Housing |

|

| End caps and fixing straps |

|

| Gaskets |

|

| Method of construction |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|

Notifications