Cugnot Xtrem

ø100 and ø133 tube light for extreme industrial atmospheres

Ever thought that the most durable lighting solution for large open spaces might just be a tubular luminaire?

The Fresnel LED is designed to illuminate large open areas with high ceilings. These lights are corrosion-resistant and easy to clean with no risk of parts going astray as they are fully sealed. These models also withstand high temperatures and voltage surges, guaranteeing a far longer life than a traditional industrial floodlight.

Corrosive substances, acid vapours

Oils & hydrocarbons

UV radiation and bad weather

Dust and extreme grime

All types of humidity

Washing with a high-pressure jet

Health and safety requirements according to IFS, BRC and HACCP texts

Permanent use at temperatures of up to 50°C

Extreme variation in temperature

Repeated turning on and off

Mechanical impacts Intense and repetitive vibrations

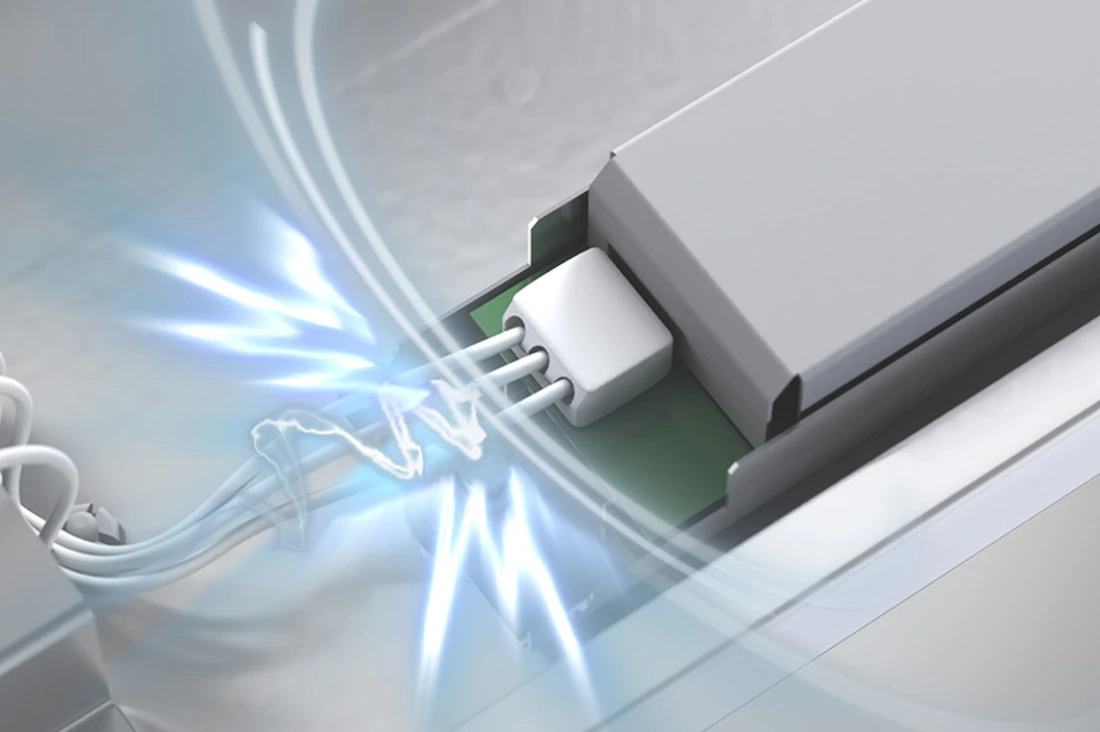

Voltage surges up to 4 kV, power surges

Forget those heavy, unwieldy cast aluminium spotlights: Sammode has come up with a new and more affordable alternative offering nothing but benefits: a powerful, efficient and reliable LED driver in an ultra-light tubular housing suitable for the harshest industrial environments. Who could ask for more?

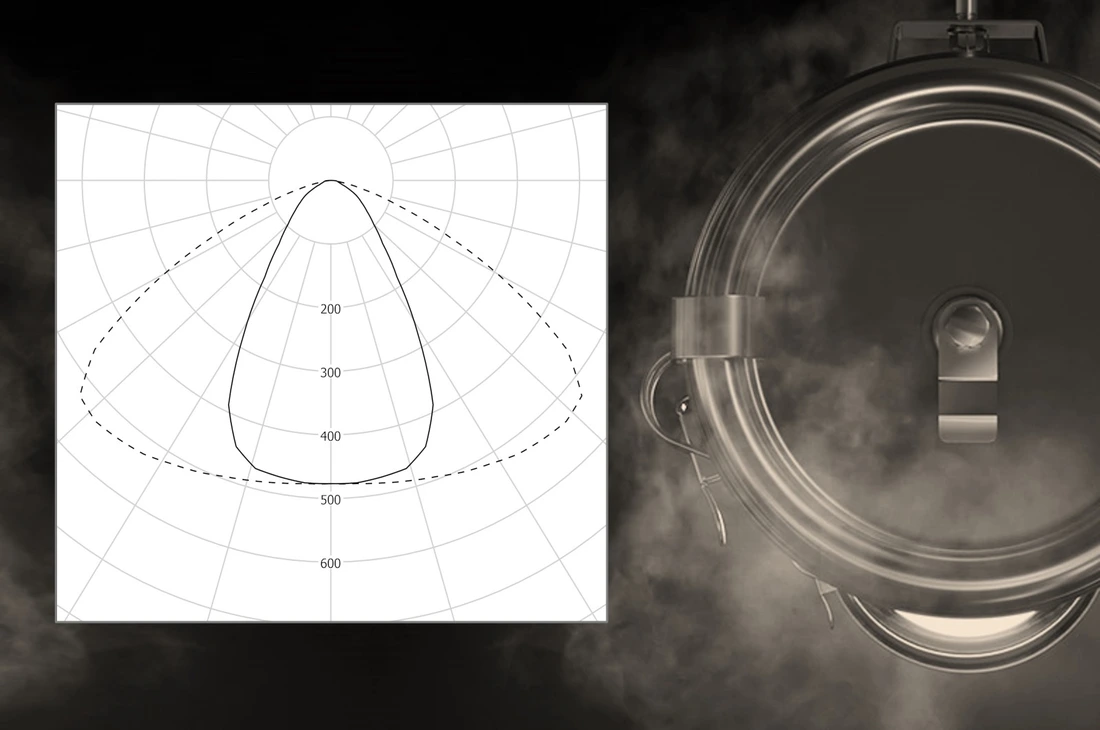

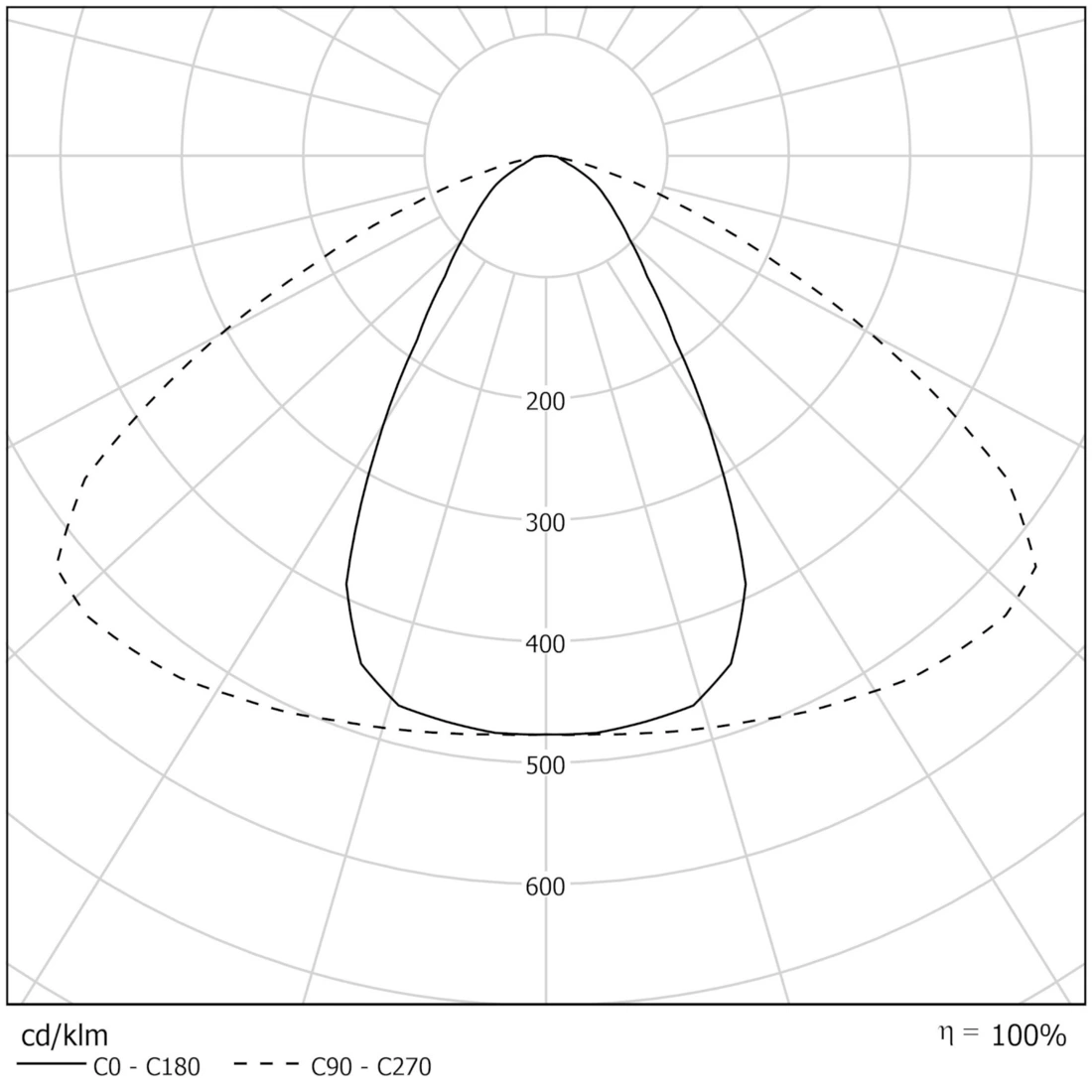

Optimised lighting in large industrial areas, where heights can reach up to 15 m, requires strong luminance and lights designed for intensive use. How do we manage it? High-performance LED modules combined with an elliptical beam linear lens, providing durable, low-energy lighting right where you need it.

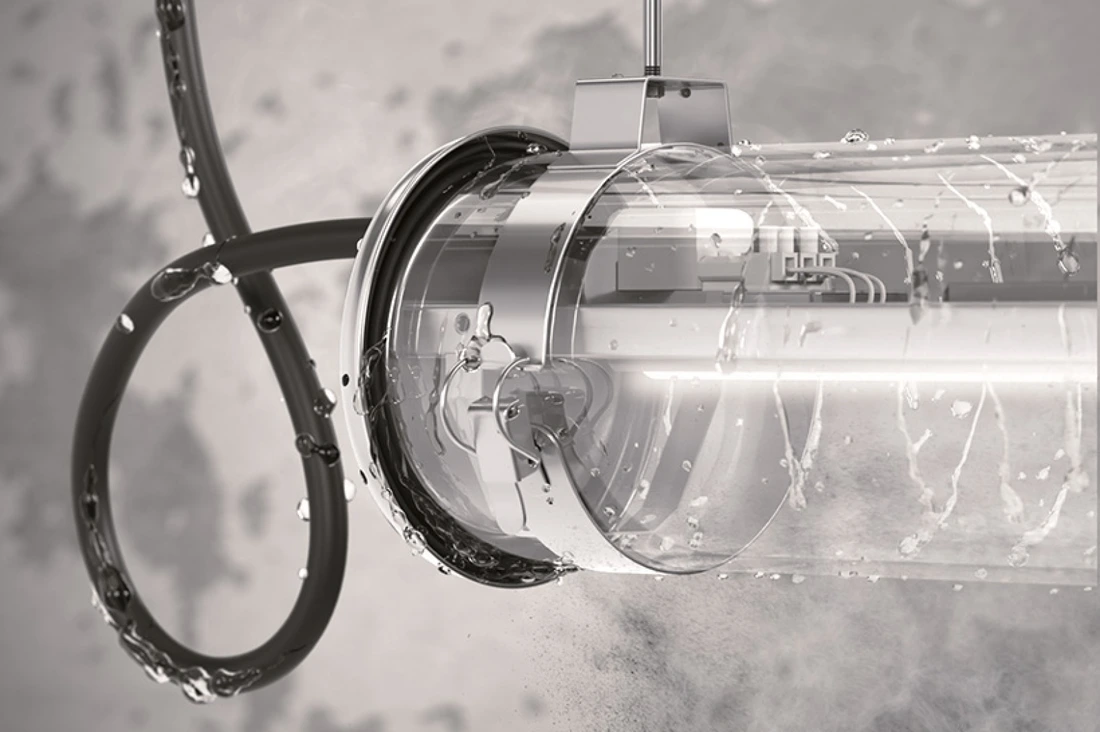

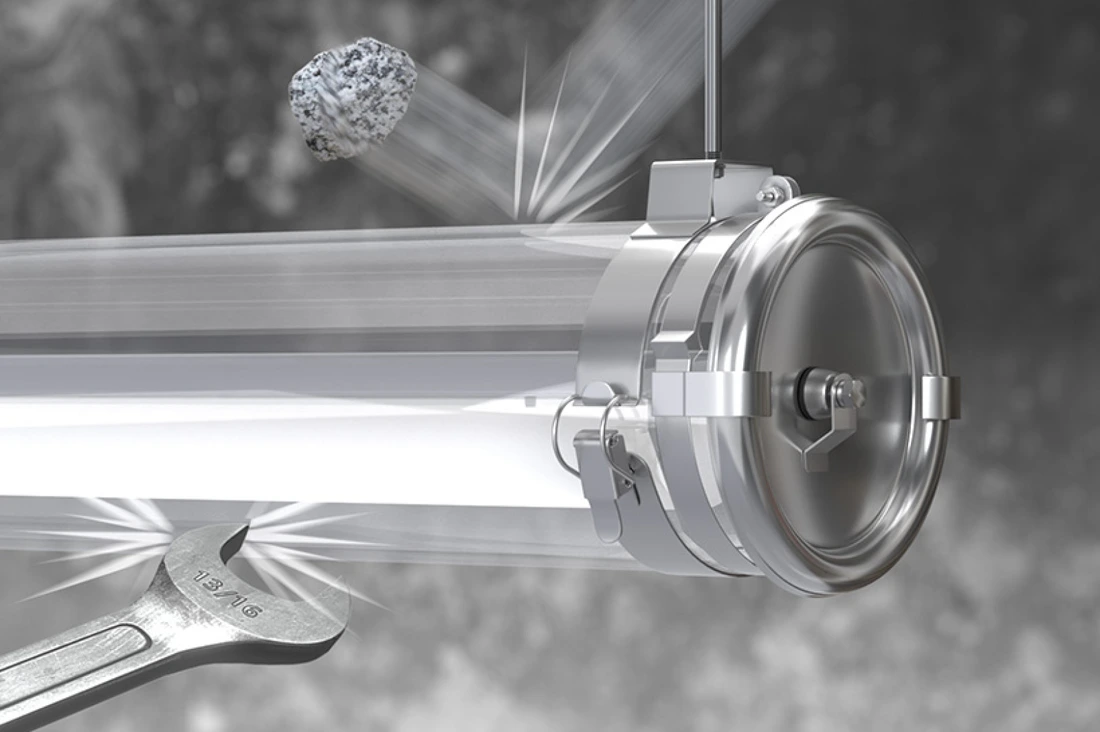

Forget fine dust, high-pressure jets, corrosive substances and the like. Thanks to its 3-seal system and uniform tightening with a central screw (the Screw© system), the housing remains firmly sealed, even when the temperature varies significantly. IP68, IP69K, everywhere and well into the future!

Even the very best housing cannot stand up to the potential effects of an at-risk network. With this in mind, Sammode has opted for the most reliable components available, designed to withstand electrical disturbance, voltage surges, extensive temperature variation and vibrations.

External 100% stainless steel parts, combined with a composite diffuser in co-extruded polycarbonate-PMMA, offering exceptional resistance to detergents, acid vapours, IK10 mechanical impacts and UV radiation.

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Valid even for 24/7 use at the maximum operating temperature for the product. 8-year warranty you will not find anywhere else on the market, reflecting our unfailing commitment to our customers!

Even after 15 or 20 years’ use, every single part we supply can be easily replaced, with no need to send it back to us. No one else offers a guarantee of lifelong lighting solutions!

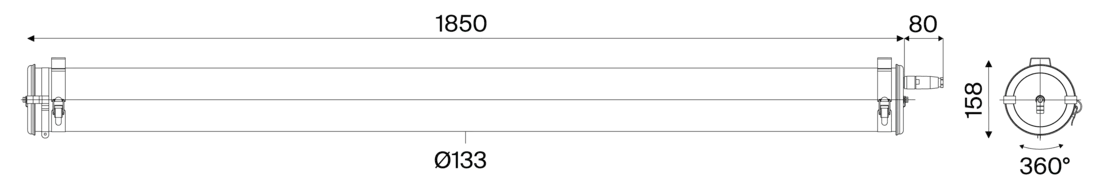

|  |  |

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|---|---|---|---|---|---|---|---|---|

| 11100 | 1850 | FRE133 26H840 POME PS3 BRS | 32115035 | 75 | Data sheet | Plan | STEP DS | .TXT | Download all |

| Polyamide capacity Ø5-12mm | 113 |

| Polyamide capacity Ø7-14mm | 116 |

| Nickel-coated brass capacity Ø5-14 mm | 113LN |

| IP68/69K quick-lock plug with threaded ring (capacity: Ø8 to 10 mm) | PS3 |

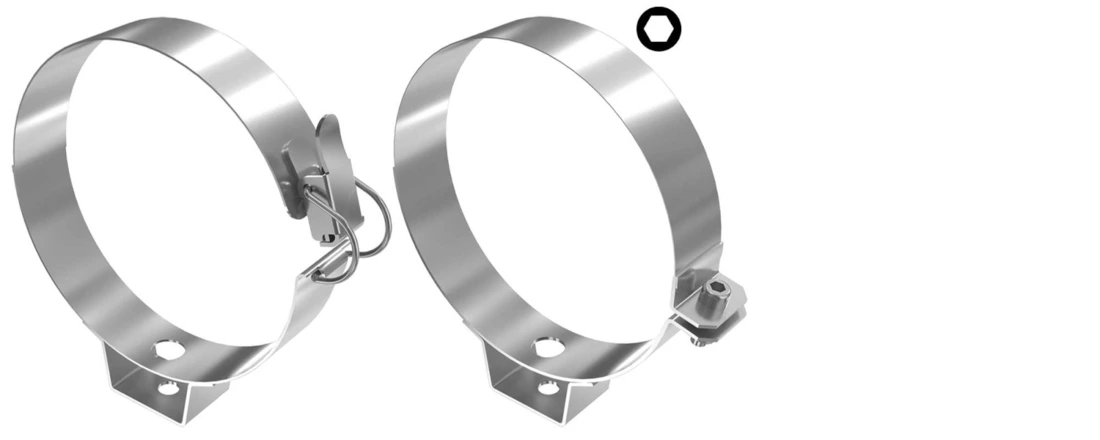

| Reinforced fixing straps | BRS |

| Reinforced fixing straps with HSHC screw | BRV |

| Polycarbonate housing | PO |

| Coextruded polycarbonate/ PMMA housing with high chemical resistance | POME |

| End caps & fixing straps 304L stainless steel | - |

| End caps & fixing straps 316L stainless steel | MR |

| 3000K | 830 |

| 4000K | 840 |

| 5000K | 850 |

| Electronic gear unit for DALI 2 dimming | RD |

1m HO7-RNF Xtrem pre-wired cable 3G1,5²

1m HO7-RNF Xtrem pre-wired cable 3G1,5² | Stripped free end CAB0285 | |

| Wieland® plug IP68/IP69K (capacity : Ø10-14mm) CAB0286 | |

| Wieland® plug and Y spliter for loop-in/out CAB0287 |

| Light source |

|

| Heat management |

|

| Control gear |

|

| Supply voltage |

|

| Electrical class |

|

| Operating temperature |

|

| Optics |

|

| Connection |

|

| Mounting |

|

| LED engine maintenance |

|

| Housing |

|

| End caps and fixing straps |

|

| Gaskets |

|

| Method of construction |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|

Notifications