Pascal

Tube ø100 and 133 for industrial atmospheres

An innovative light fixture offering extra lighting comfort for your maintenance pits

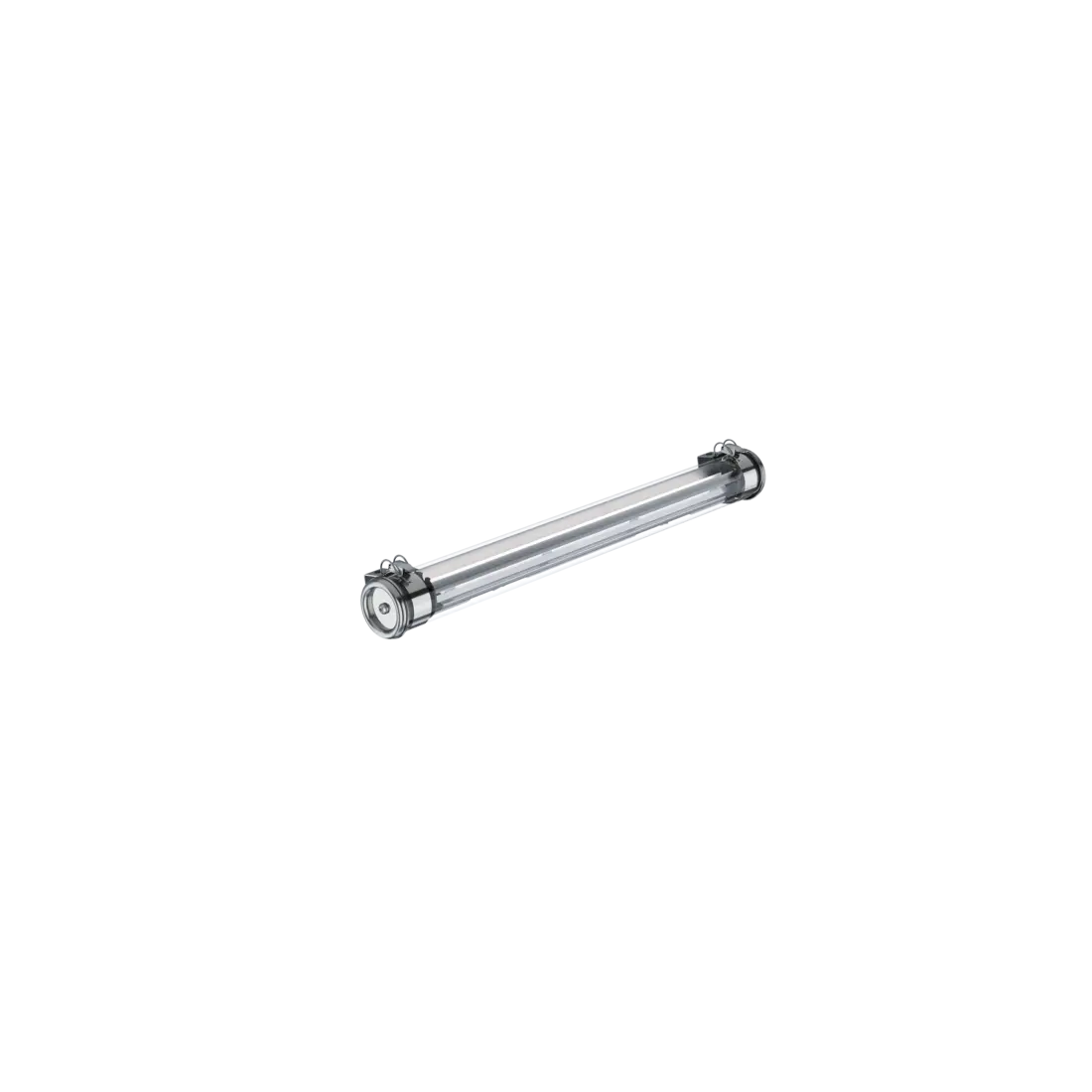

The Niepce FV is the ideal luminaire for maintenance pit lighting. This compact, well-sealed model can withstand impacts, vibrations and oil splashes, and is fitted with dual-focused beams able to provide even lighting on the underside of a carriage or in the bottom of a pit, without dazzling the operator.

Corrosive substances, acid vapours

Oils & hydrocarbons

UV radiation and bad weather

Dust and humidity

Washing with a high-pressure jet

Permanent use at temperatures of up to 35°C

Extreme variation in temperature

Repeated turning on and off

Heavy mechanical impacts

Intense and repetitive vibrations

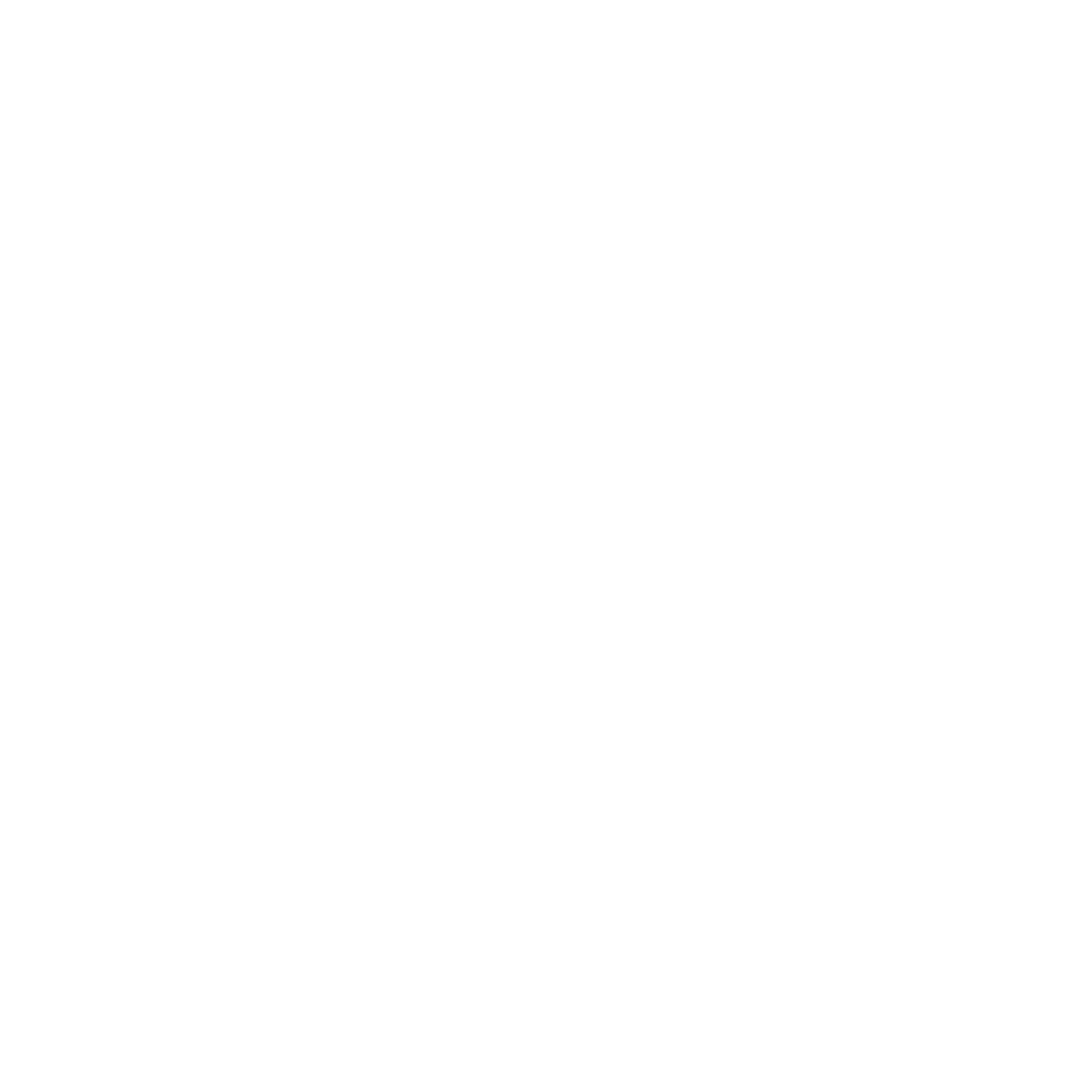

The NIEPCE FV is the ideal LED luminaire for maintenance pit lighting. When installed in a staggered layout on either side of the pit, only a few luminaires are needed to provide the required amount of light in key locations, with remarkable uniform lighting and low energy consumption.

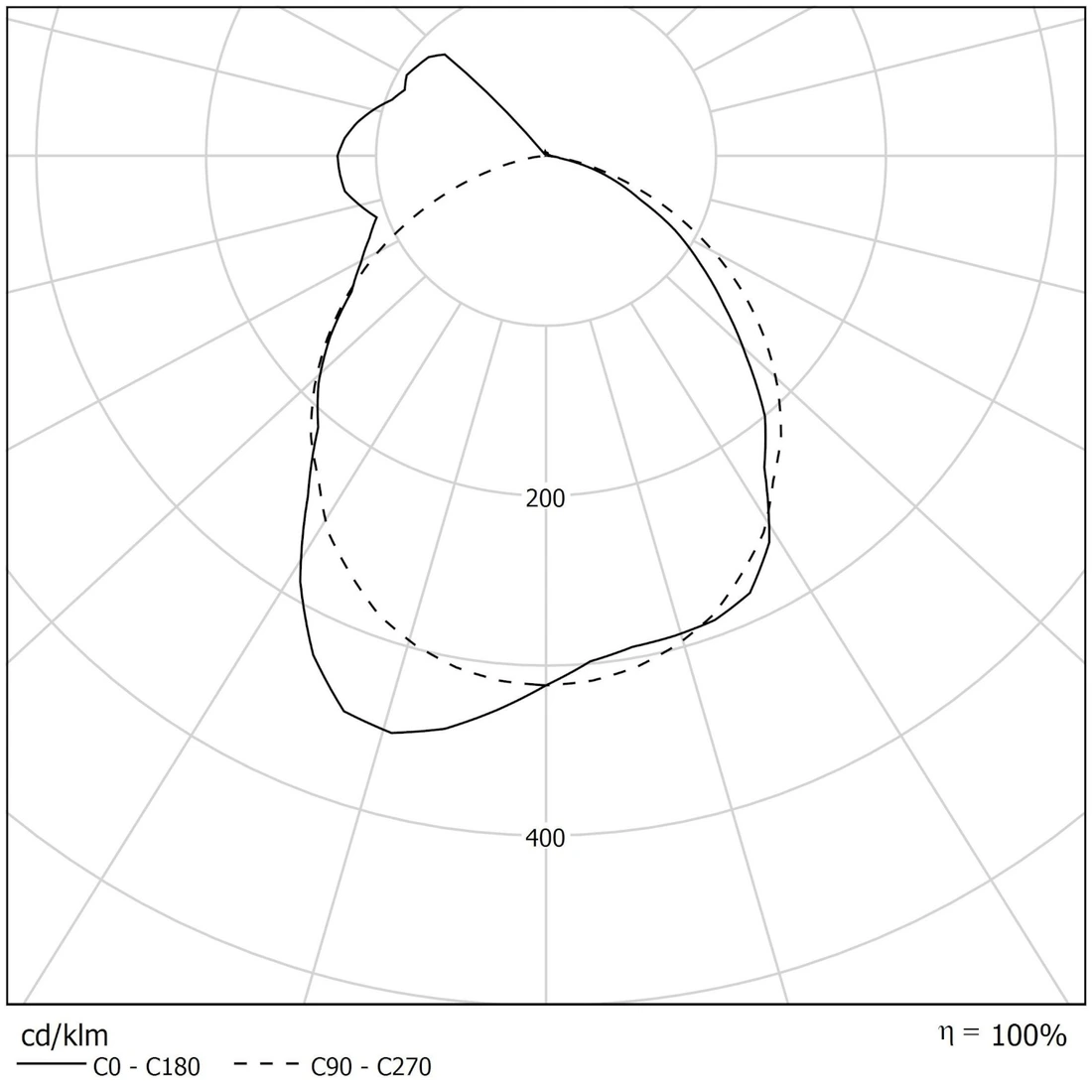

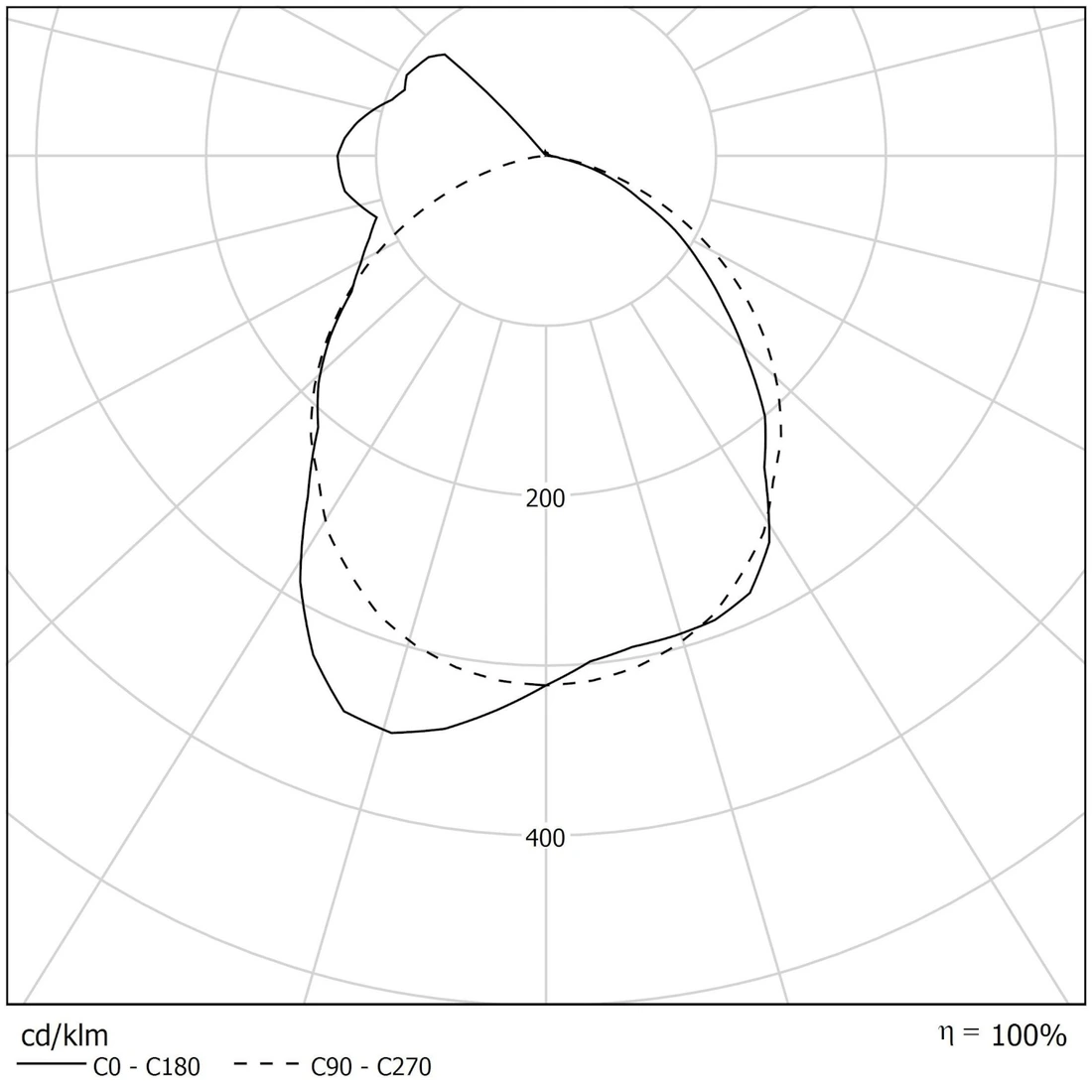

The dual-oriented optics designed by Sammode provide homogeneous lighting on the underside of a carriage and enough light at the bottom of the pit to grab tools and avoid any obstacles during movements. Glare is also minimal, ensuring real visual comfort for maintenance and inspection teams.

Inspection pits are narrow working spaces and particularly tough environments for luminaires, due to impacts when handling tools. By opting for homogeneous materials with exceptional mechanical strength and no mating surfaces, the Sammode housing can withstand impacts (IK10) and vibrations, no matter how tough.

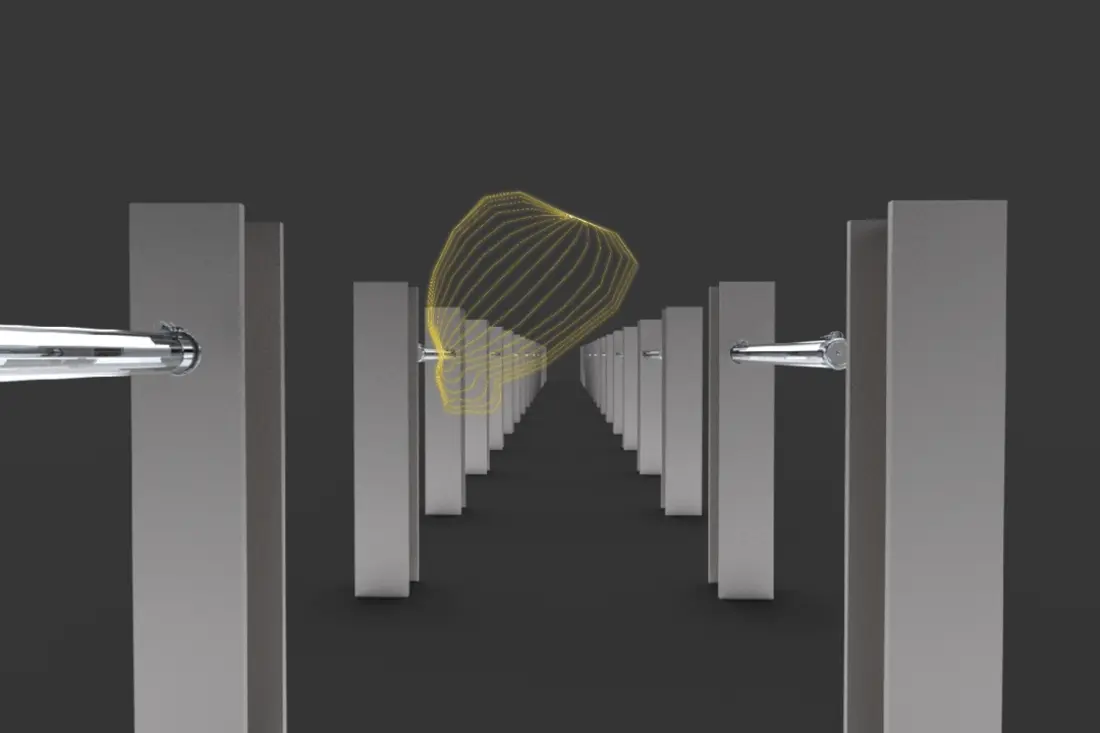

Sammode launched the NIEPCE FV to face the ultimate challenge: adapt to any cable configuration in the pit. The internal gear tray, equipped with the patented Close’n Connect© automatic connection system, is reversible, meaning you can decide on which side to connect the luminaire at the site itself.

Sammode opted for a co-extruded composite diffuser for this specific application, combining the mechanical solidity of co-polycarbonate with the oil- and hydrocarbon-resistant properties of PMMA. A 3-seal system is fitted at both ends, guaranteeing optimal luminaire sealing (IP68, IP69K) that stands the test of time.

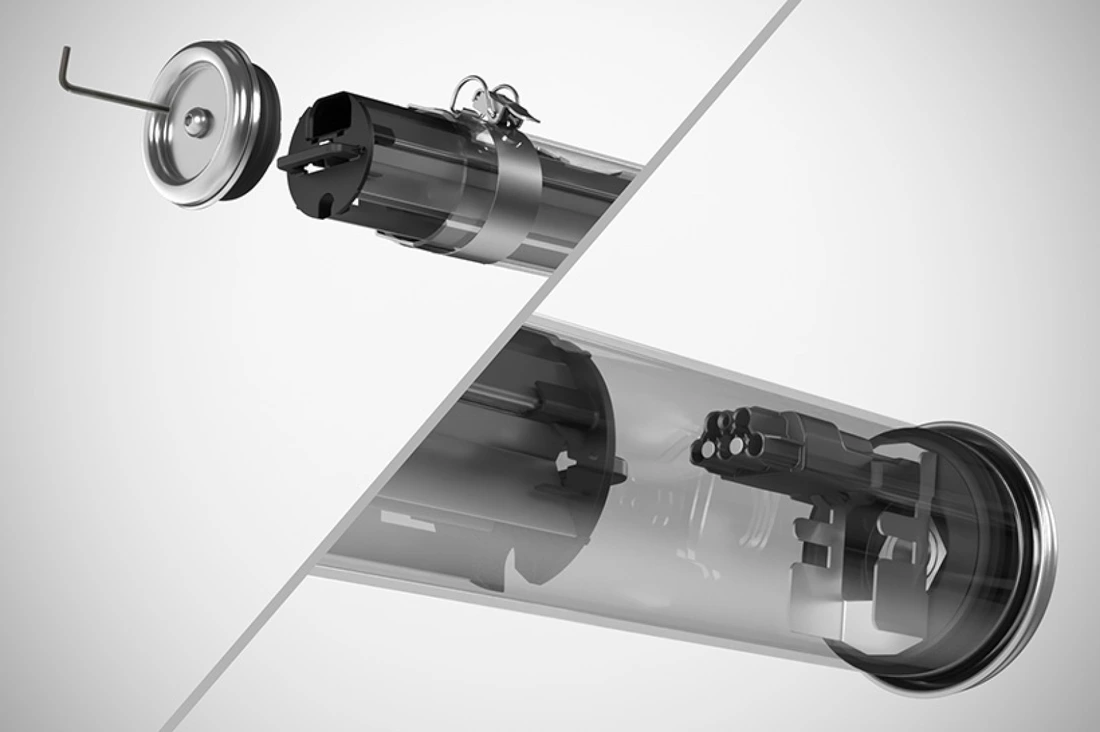

Save up to 90% on the energy bill by only turning the lights on when necessary, thanks to our optional motion sensor. A high-strength sensor built into one or several master luminaires can then control slave luminaires in the same line equipped with the switch-off warning function (RC function).

Designed and manufactured in France, keeping supply chains short and using durable components and materials, primarily sourced in Europe. Each luminaire is manufactured, assembled and inspected by our teams with full traceability.

Valid even for 24/7 use at the maximum operating temperature for the product. 8-year warranty you will not find anywhere else on the market, reflecting our unfailing commitment to our customers!

Unlike the disposable world we live in, Sammode lights are designed as modular systems. New technology can be integrated in existing fixtures: simply replace the outdated parts!

|   |

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|---|---|---|---|---|---|---|---|---|

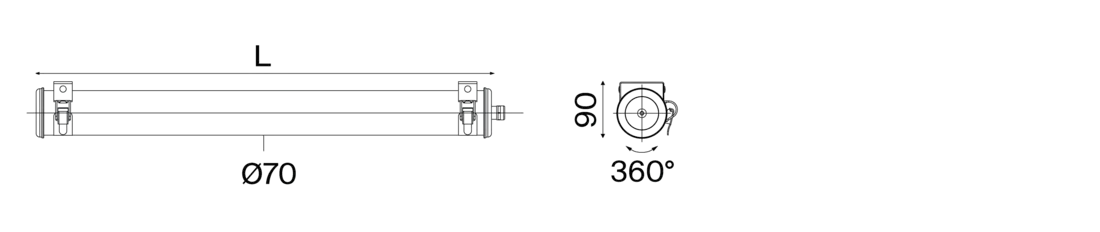

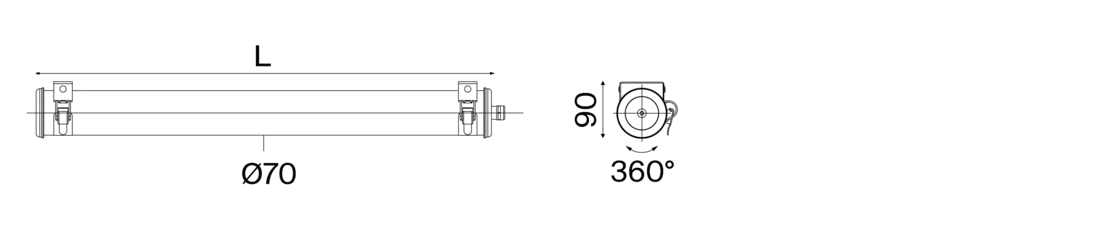

| 1700 | 715 | NIE70 FV 12H840 POME 113LN | 19950010 | 14 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 3000 | 995 | NIE70 FV 13H840 POME 113LN | 19950020 | 25 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 4300 | 1275 | NIE70 FV 14H840 POME 113LN | 19950030 | 35 | Data sheet | Plan | STEP DS | .TXT | Download all |

|   |

| Flux (lm) | L (mm) | Designation | Code | Watt | Data sheet | Plan | STEP DS | .TXT | Download all |

|---|---|---|---|---|---|---|---|---|---|

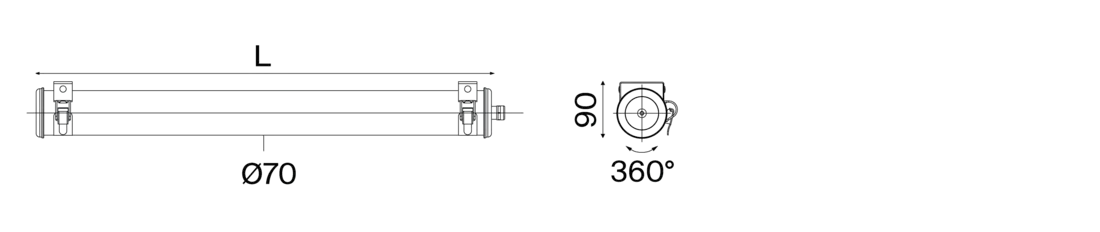

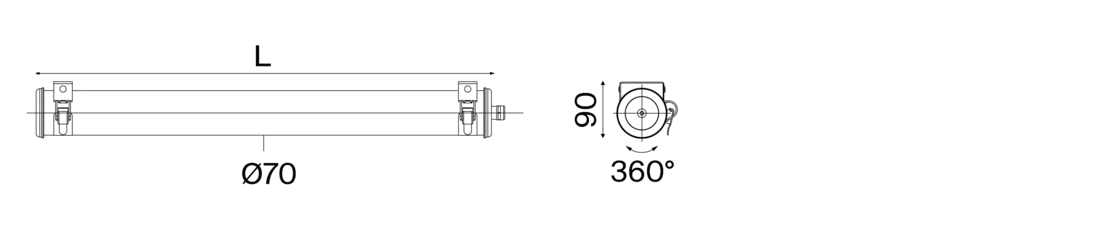

| 1700 | 715 | NIE70 FV 12H840 TR POME 113LN | 19950013 | 14 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 3000 | 995 | NIE70 FV 13H840 TR POME 113LN | 19950005 | 25 | Data sheet | Plan | STEP DS | .TXT | Download all |

| 4300 | 1275 | NIE70 FV 14H840 TR POME 113LN | 19950003 | 35 | Data sheet | Plan | STEP DS | .TXT | Download all |

| Nickel-coated brass capacity Ø5-14 mm | 113LN |

| IP68/69K quick-lock plug with threaded ring (capacity: Ø8 to 10 mm) | PS2/PS3 |

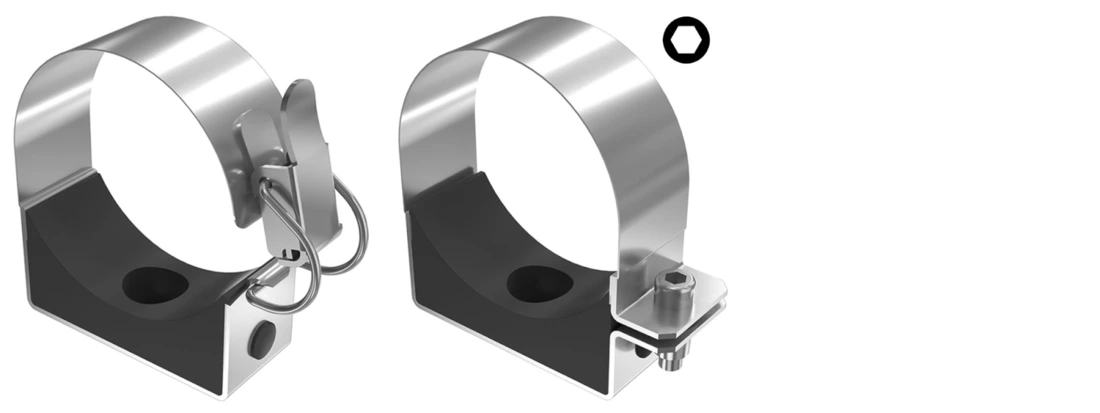

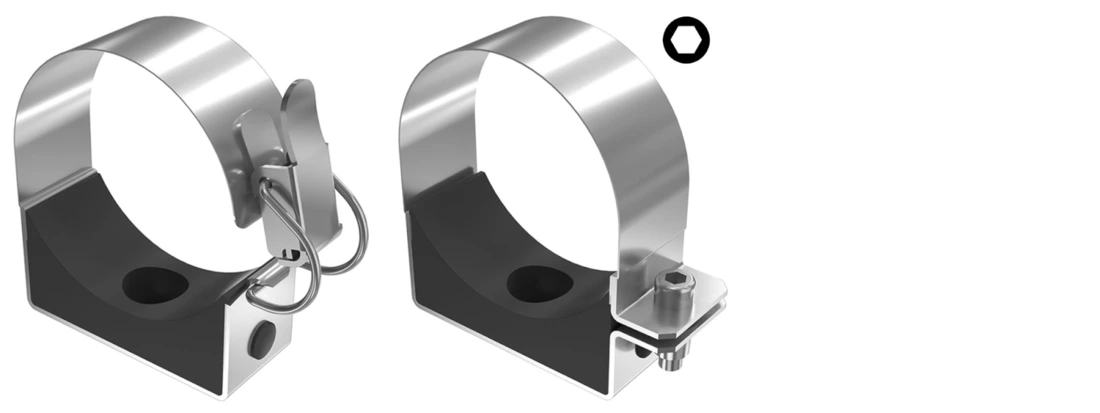

| Fixing straps | - |

| Fixing straps with HSHC screw | BAV |

| Polycarbonate housing | PO |

| Coextruded polycarbonate/ PMMA housing with high chemical resistance | POME |

| End caps & fixing straps 304L stainless steel | - |

| End caps & fixing straps 316L stainless steel | MR |

| 3000K | 830 |

| 4000K | 840 |

| 5000K | 850 |

| Electronic gear unit for DALI 2 dimming | RD |

| Switch-off warning function (for sensor/timer) | RC |

| Built-in presence sensor (length increased by 85mm) | SI |

| Class I | - |

| Class II | CL2 |

| IP68 4-outlet junction box (capacity Ø7-14mm) CP00674 |

| Stripped free end CAB0080 | |

| Wieland® plug IP68/IP69K (capacity : Ø10-14mm) CAB0095 | |

| Wieland® plug and Y spliter for loop-in/out CAB0145 |

| Light source |

|

| Optics |

|

| Heat management |

|

| Control gear |

|

| Supply voltage |

|

| Electrical class |

|

| Operating temperature |

|

| Connection |

|

| Mounting |

|

| LED engine maintenance |

|

| Housing |

|

| End caps and fixing straps |

|

| Gaskets |

|

| Method of construction |

|

| Waterproofness |

|

| Resistance to IK shocks |

|

| Fire resistance |

|

| Vibration resistance |

|